Over the past few weeks, here at Watchadvice we have been showcasing and discussing some of the most common certifications given to wristwatches. We started out with the Certified chronometer and the standards of the COSC here, then delved into the more technical and comprehensive METAS Master chronometer certification here. The third and most intensive certification watch manufacturers seek to obtain is the seal of Geneva which was discussed here.

So to close out this series we are taking a look at some of the other big players in chronometry standards certifications, like Rolex’s superlative chronometer standard, Jaeger Le-Coultre’s master 1,000 hours control test, the Patek Phillippe seal and more.

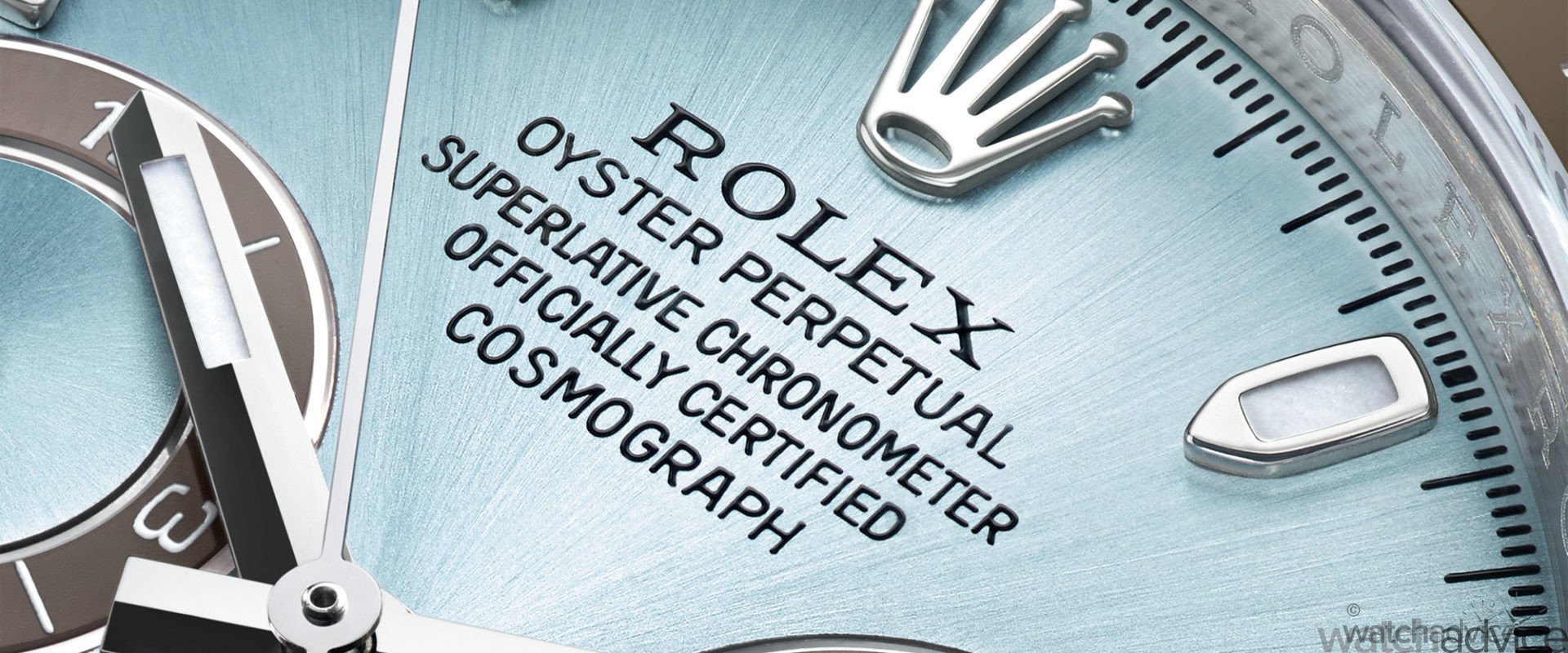

Perhaps the most commonly known of the remaining certifications, is that of the Superlative Chronometer by Rolex. As the worlds highest selling and most popular luxury watch brand, said to be churning out up to one million pieces a year, the words “Superlative Chronometer” have been printed onto an unfathomable number of dials.

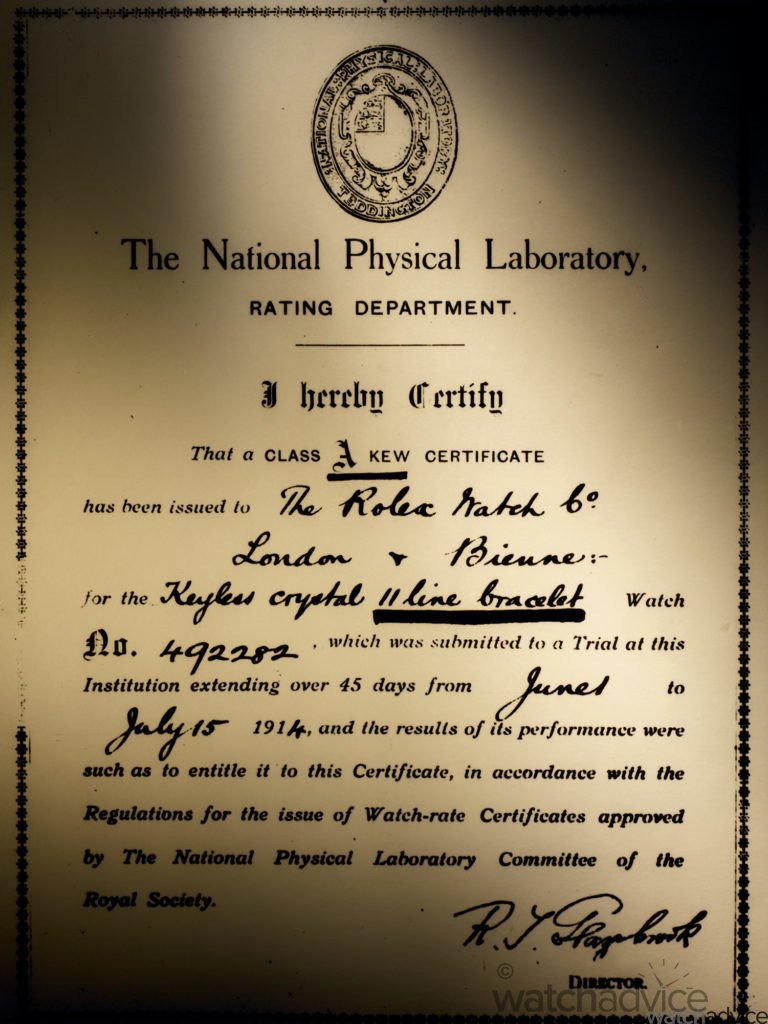

Back in 1951, the house that Hans Wilsdorf built, Rolex, began the arduous task of having every single movement they would sell, certified as a Chronometer by the COSC. Then, just six years later in 1957, the brand began stamping their dials with the words “Superlative Chronometer” to denote a superior level of chronometric precision. However, it was not until 2015, some 58 years later, that Rolex began to really tighten the screws on its timepieces, offering consumers with a staggering guarantee.

Each and every watch that Rolex ships, is guaranteed to keep time at a rate of -2 to +2 seconds per day. A precision that holds the watch to at worst, a variance of just 12 minutes over a calendar year, this is a staggering feat of engineering prowess on display at Rolex, when taking into account the roughly one million movements being shipped each year.

Whilst you will rarely find the level of hand finishing and intricate complications that brands such as Vacheron Constantin, or Audemars Piguet display, the continued pursuit of excellence and consistency held by Rolex, is a large part of what has lead them to their current position in the marketplace.

Moving into the realms of hand made and ultra-high-end timepieces, we find the Fleurier quality foundation, Haute horology certification. The Qualite Fleurier label purports to be an absolute guarantee of quality and provenance for luxury wristwatches. With some of the worlds best manufacturers participating in the standard. Brands such as Chopard, Bovet and Parmigiani Fleurier subject their watches to the strict standards of the Qualite Fleurier.

In order to be granted the stamp of the FQF, timepieces must firstly be 100% manufactured in Switzerland and then pass the COSC chronometer testing, before being subject to strict aesthetic standards.

These aesthetic standards dictate that the movement of the watch must display a finishing level of exclusive quality, a simple engine turned perlage or Coates-de-Geneve simply will not do for the Qualite Fleurier. All materials of the movement must be independently inspected and signed off prior to assembly, with only metal, technical ceramics, precious or avant-garde materials available to the manufacturer.

What differentiates the Qualite Fleurier, is their “Chronofiable” testing which takes place after the assembly of the piece. The manufacturer must provide multiple examples of the pieces for testing, even for limited production schedules, these will then undergo a series of tests to determine the ageing process of the watch, the precision and strength of any pusher and crown, shock, water and magnetic resistance.

Finally, the finished watch is subject to the “Fleuritest” simulation, whereby the piece must undergo a 24 hour cycle inside a robotic simulator. The simulator is designed to test the watch in a range of conditions similar to daily wear, and to ensure chronometric precision of -0 to +5 seconds per day, similar to that of the METAS standard.

Upon successful completion of all testing, the watch is awarded with the FQF, La Haute Horlogerie certifiée.

Staying in the world of Haute horology, Patek Phillippe who were once a fervent supporter of the Geneva Seal, decided in 2009 to part ways with the institute, creating the Patek Phillippe seal in its stead.

Patek have taken a less restrictive approach to certification with the creation of their own standard, doing away with the locale restrictions placed upon brands by the Geneva Seal, and opening up the available manufacturing processes for modernisation within the company.

Patek state that the criteria applied to their timepieces for certification are some of the strictest in the industry, although they have been less than transparent in discussing those criteria since the inception of the Patek Phillippe seal.

What is known, is that that the certification applies to the watch in its entirety, including peripheral features like bracelets, straps and clasps. In terms of time keeping, Patek Phillippe ensure precision of -3/+2 seconds per day for each of their timepieces.

Perhaps the most impressive addition to the brands repertoire, is that they now guarantee that the quality seal for watches also covers service for the entire lifetime of the watch, and guarantees maintenance, repairs, and restoration of all watches crafted by the manufacture since 1839.

Finally, we have one of the most intensive testing regimes employed by any luxury watch manufacturer to date. Jaeger Le-Coultre’s master control 1,000 hours test.

The 1,000 hour control testing is a system of internal certifications by the brand for each model that they offer. Each models 1,000 hour test is tailored to the pieces complication, and specifications to ensure excellent performance throughout its intended use. These tests include chronometric precision, shock resistance, climate resistance, water proofing and even accelerated ageing of straps to ensure their stability.

These tests are conducted throughout the manufacturing process of the watch, and are conducted on the bare movement and the cased watch to maintain consistency throughout the model line.

JLC put each of their models through the ringer to offer an unrivalled assurance of quality for the end user.