We take a deep dive into the in-house movements of Hublot and look at why these movements and pieces are needed in the Watch Industry!

This article is written in partnership with Hublot

Just 2 weeks ago, Hublot was awarded the Red Dot Award for Product Design 2024 for their innovative MP-10 Tourbillon Weight Energy System. This is the piece that Hubot unveiled at LVMH Watch Week 2024 and even though it was released this year after the MP-15, the designated MP-10 took 5 years more in development than planned due to its complexity and Hublot’s exacting standards and goals to make this piece a reality. A piece like the MP-10 showcases exactly what Hublot is about, and why they do what they do. They are not here to conform to the norms of watchmaking but in the words of Ricardo Guadalupe when I had the pleasure of talking with him at Watches & Wonders 2024, they are always pushing the boundaries and trying to break conventions. Say what you like about Hublot, but this is exactly why the industry needs a brand like Hublot – to push the boundaries, break the conventions, and showcase what is possible in the world of watches.

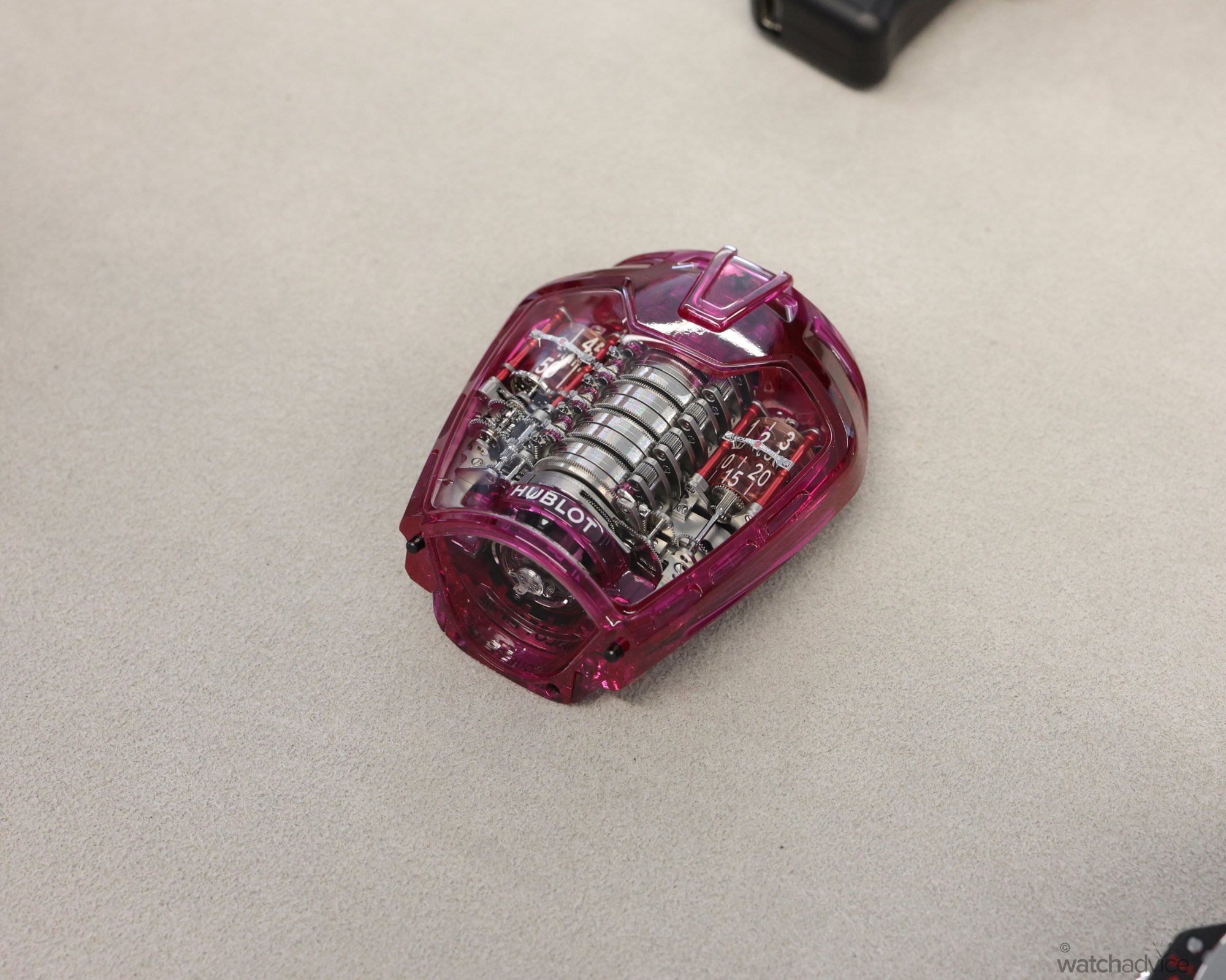

What makes this movement (outside of the very non-traditional case shape and design) so special and worthy of the Red Dot Award? Hublot has completely re-invented the way the movement operates from the winding system to the time indicators that tell you the hours and minutes – hence the name, Weight Energy System. The two white gold weights on either side of the watch, which you can see in the middle image above with MP-10 on the side, slide back and forth directing the energy to the barrel as you would see in a typical rotor winding system. It sounds easy enough in theory, but incredibly hard to do in practice and perfect. In addition to this, the energy is then transferred to the rotating displays on top, which are positioned under a hidden magnifying glass to tell you the hours and minutes, and the tourbillon is positioned on a vertical incline as well as being built into the second’s display disc – all of which is a design that Hublot has now applied for a patent on this due to its uniqueness.

This whole package put together is just one example of how Hublot innovates across the board. This got us thinking about Hublot’s movements, from their highly complicated pieces as a part of their Manufacture Piece (MP) collection, all the way to their everyday pieces, such as the Big Bang Unico and Meca-10. We all know Hublot is a brand that has received a lot of criticism over the years, and whether you agree with it or not, the one thing you can’t deny is their ability to push the boundaries within watchmaking. This is nothing new for the brand either. All the way from 1980 when Carlo Crocco put a rubber strap on a gold watch, through to the Avante Garde days when watch-industry icon Jean-Clade Biver headed up the brand. Fast forward to today, with Ricardo Guadalupe at the helm focused on their technical expertise in material innovation and movement design, propelling it into the future with big plans. One of these is to develop more movements in-house and expand its manufacture with a third building measuring 16,000 square feet to produce up to 60% of their movements in-house.

Hublot is a brand that isn’t constrained by two centuries of heritage and tradition, so it has free reign to carve out its own course in watch history. Let’s face it, Hublot has been doing this now for 44 years and isn’t afraid of some nay-sayers as with any brand, there will always be detractors, but on the flip side, you inevitably have those who love the brand and what it stands for and does. The trick for any brand in any industry is leaning into this brand love and expanding this circle of influence slowly. Just like laughter is infectious, so are people who are promoters of a brand, especially those who really understand it at a deeper level. Admittedly, I as a watch lover have been there with Hublot – I’ve loved it to the point it was a grail of mine at one point, and then I jumped on the bandwagon of those who were not so kind to the brand, following this sheep so to speak, and now, being a lot more educated, not to mention a little older and wiser and less caring about what people think, I’m back to admiring Hublot, what they are doing in the world of watches as well as just thinking they do some great pieces which look uber-cool on the wrist.

The Manufacture Piece (MP) Collection

When you look at Hublot’s Manufacture Piece (MP) collection specifically, they have been innovating and breaking ground on their movements since the release of the very first MP-01 in 2011, which was effectively the precursor to the Spirit of Big Bang. But perhaps one of the most groundbreaking of these Manufacture Pieces (at the time) was the MP-05 LaFerrari from 2013 – a piece that was designed with the car in mind and in conjunction with the team at Ferrari, evident in the shape of the case and movement designed to be representative of the LaFerrari’s engine. The MP-05 houses a movement that has a 50-day power reserve, that’s 50 DAYS not hours! This set a world record at the time for a manually wound tourbillon wristwatch and was achieved by placing 11 barrels in succession to deliver this to the vertical tourbillon at the end of the piece. This has become one of Hublot’s most iconic Manufacture Pieces and sought-after watches, given they only made 50 for sale. We were lucky enough to see the prototype on our recent visit to the Hublot Manufacture in Nyon, and it is impressive in person.

RELATED READING: Watch Advice Visits The Hublot Manufacture

Over the last couple of years, Hublot’s MP collection has gone from strength to strength, both in case design and movements. Whilst many of these have unique and industry-first movements, I would go out on a limb to say that since the release of the MP-11, Hublot’s MP collection has been a masterclass in engineering and design. The first to note that immediately comes to mind is the MP-11, mostly due to the fact Hublot brought out a new version of this piece at Watches & Wonders this year – the MP-11 Water Blue Sapphire. Taking the movement innovation from the LaFerrari, Hublot has put this into a much more everyday wearable piece with a 14-day power reserve.

Originally released in 2018 at Baselworld, the MP-11 broke ground due to its long power reserve and movement configuration that put the power unit front and center of the watch. In the LaFerrari, this configuration made sense due to the unique way the movement was designed to represent the engine in the Ferrari. However, in the MP-11, Hublot took a conventional movement on a round-face watch and applied the vertically consecutive barrels to the piece. The one clear benefit to this, other than the 14 days worth of power, is this configuration was able to keep the watch to a respectable thickness. In the case of the new Water Blue Sapphire, it’s 14.4mm thick, which to put this into context, is only 0.8mm thicker than the new, slimmer Tudor Black Bay Monochrome from this year. So it’s highly wearable.

Post the MP-11, the MP-13 Bi-Axis Tourbillon Retrograde showcased yet another movement innovation, one that very few if any watch brands have done. A retrograde hours and minutes arc to tell the time, housed in a carbon or titanium case with a bi-axis tourbillon at 6 o’clock. With this piece, Hublot has looked at time telling in a different way, using the retrograde arcs, meaning that the hour and minute indicators track across the arc as time goes by, then jump back to zero when the minute hand reaches 60 minutes and the hour hand reaches 12 o’clock. Many other watch brands use this as a unique way of telling the date (most commonly) but few have thought of or dared to use it for the actual hours and minutes.

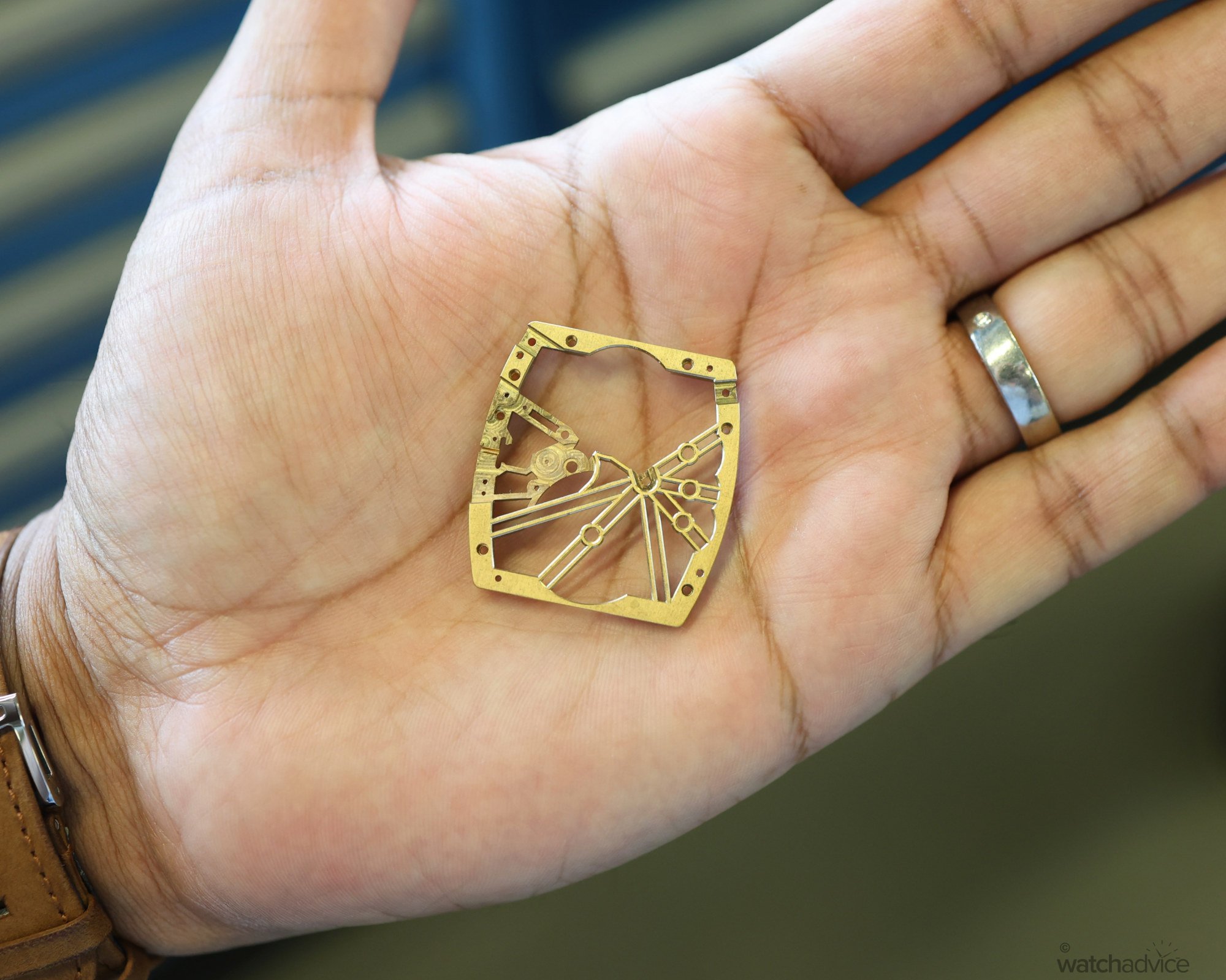

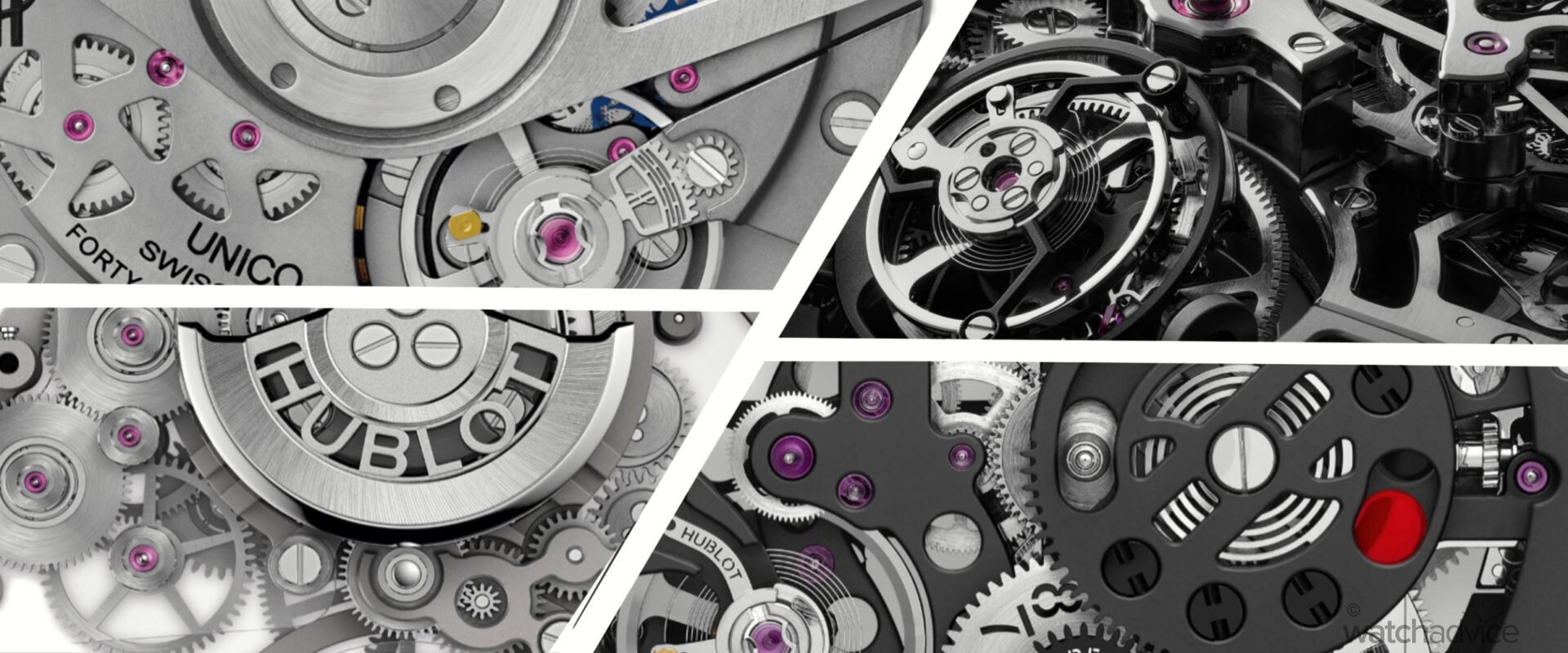

However, under the dial, you can really see what sets this movement apart and how Hublot has gone the extra mile here to design, develop, and manufacture a movement that is unique and complex, not to mention stunning to look at. If you view the image below, you can clearly see the bi-axis tourbillon cage that rotates around and on the horizontal axis, and the anglage and brushed finishes across the different elements of the movement. This is where the individual watchmakers at Hublot come into their own, having trained for many years to master these types of movements, of which, only a handful can actually do it.

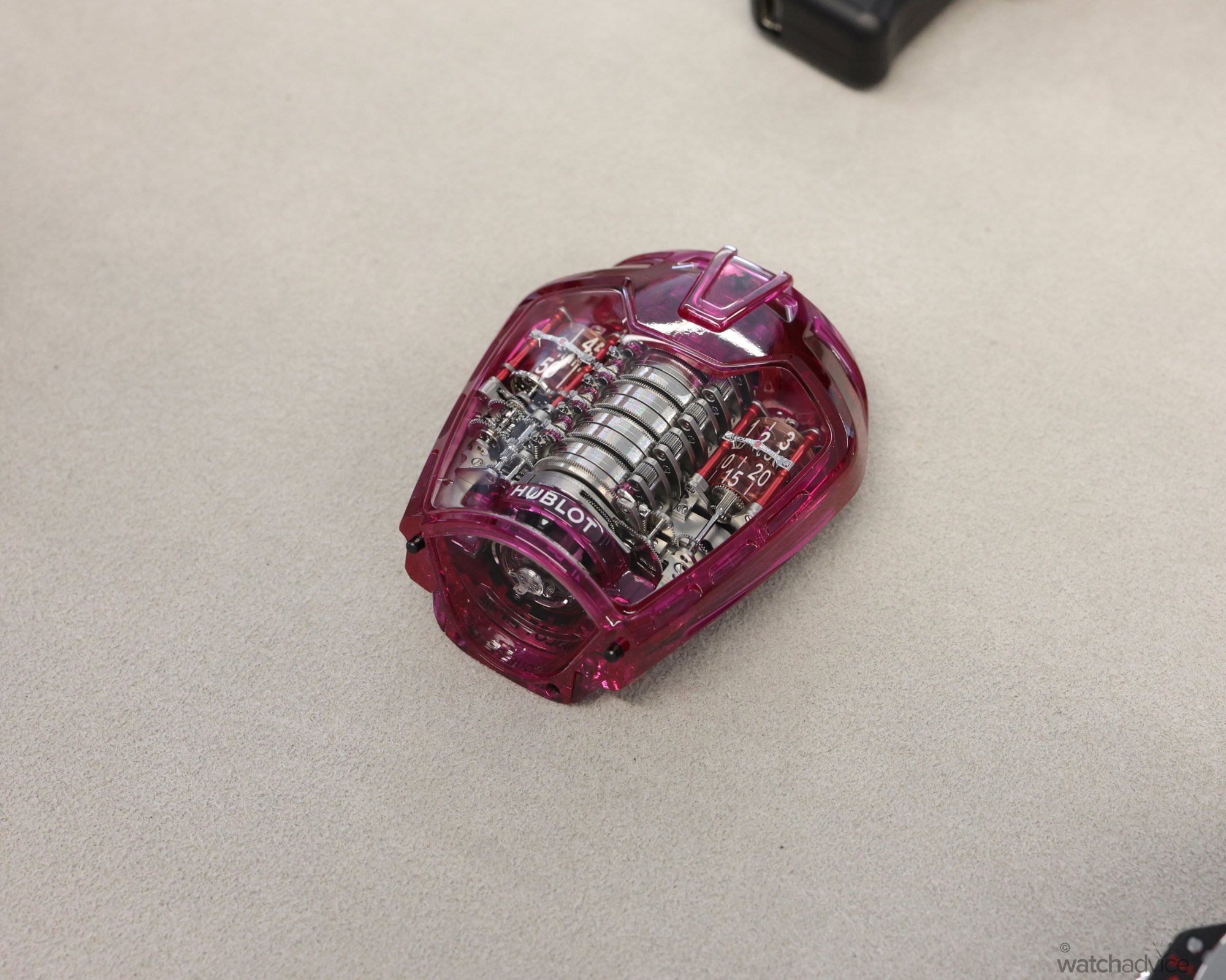

At the end of last year, Hublot teamed up for the third time with renowned Japanese Artist, Takashi Murakami to produce the MP-15 Takashi Murakami Tourbillon Sapphire. Housing a centralised tourbillon movement in a full sapphire flower case, this piece showcases not only the skill of molding sapphire into unique shapes (a story for another time) but it was the first time Hublot brought to market a central flying tourbillon. Not only this, but the hands are peripheral to the central tourbillon, creating yet another level of complication.

Now interestingly enough, this piece was met with some polarising views. Those who understood the piece, what it represented, and the reason for it being a flower (Takashi Murakami’s signature design) instantly got it. Even if they didn’t understand the complexity of crafting a piece such as this, which after speaking to Roberto Valsangiacomo, Materials Engineer for Hublot R&D, is incredibly hard and an intricate process, there is still an appreciation there. For those who were detractors of the piece, yes it’s not a watch that will appeal to everyone, but as I’ve said many times in the past, it’s not meant to be. This is art for your wrist, and art is subjective. It’s also for fans of both Hublot and Takashi Murakami, very wealthy fans who can afford one of the 50-piece limited editions that were produced and effectively all but sold out.

Case design and construction aside, the movement in this is yet another example of Hublot’s thinking of how to deliver a very unique piece with matching internal workings. Central tourbillon movements are notoriously hard to design and create, and adding to this, the list of people who have the know how to do this is not long. There is a reason when you come across a high-end central tourbillon piece from any brand, you can be sure it is not going to be kind to the bank balance unless you’re in the fortunate enough position to have more than 7 zeros at the end of the double digits on your last statement.

In traditional watchmaking, the tourbillon usually takes the place of the balance wheel, effectively being a rotating version of this to offset the effects of gravity. However, when you look at a central tourbillon, you’re now placing this whole escapement at the center of the watch where the hour, minute, and second hand would be, and reconfiguring the set up of the movement and gear train to accommodate this, and also having the hands (in this instance) still being centrally located to tell the time. In the case of the HUB9015, the watchmakers have been able to give this 5-days of power thanks to the two barrels, adding to the complexity of the movement’s design. Don’t want to spend all that time winding the watch? Not a problem. Hublot has created a special stylus that is rechargeable via a USB socket. This stylus is placed on the crown and then winds through 100 revolutions until the barrels are fully wound. Problem solved!

RELATED READING: Is Hublot The Most Misunderstood Brand In The Industry

The latest Manufacture Piece that the brand most recently released in June is the collaboration with artist Daniel Arsham in the form of the Arsham Droplet – a unique looking pocket watch inspired by water and through its design is a three-in-one piece: A pocket watch, table clock or a pendant. Watch Advice has yet to see this piece in person, in fact as of writing this, very few versions have been seen in the flesh (or the sapphire as it were). However, this is another example of where Hublot flexes its horological muscles, not to mention giving its artistic collaborators free rein to design a piece that is unique to them.

Hublot is one of the very few brands where collaborations are that – a coming together of two parties to design something that isn’t typical of the brand. We often see collaborations between brands and external parties, but the reality is, the watch is a standard model that has aesthetic changes in most cases, but is still very much recognisable as the off-the-shelf model. In the instance of Hublot, their movement and material designers work with the artists to help bring the artist’s vision to life. With the Arsham Droplet, Hublot has given this piece Hublot’s Meca-10 manufacture movement – a manually wound calibre with a 10-day power reserve with the Luminescent Green Arsham Colour palette. And this is a perfect segue into the next section…

Hublot’s In-House Manufacture Calibres

As Hublot is still a young brand, the amount of in-house calibres it has is around 30%, which is good when you think about the time, money, and expertise it takes to develop in-house movements. Brands that have been around for 100+ years, even 200+ years have had copious amounts of time to develop their movements. They’ve had time to experiment, innovate, and amass the skills and talents it requires to design and build a movement from the ground up. But Hublot is slowly increasing this. As mentioned previously, Ricardo Guadalupe, Hublot’s CEO tells me they are on their way to having around 60% of their movements in-house once their new facility opens up in 2026. This means that more of their entry-level pieces, like the Classic Fusion will eventually have a Hublot Manufactured movement in it. But this will take time and money to do.

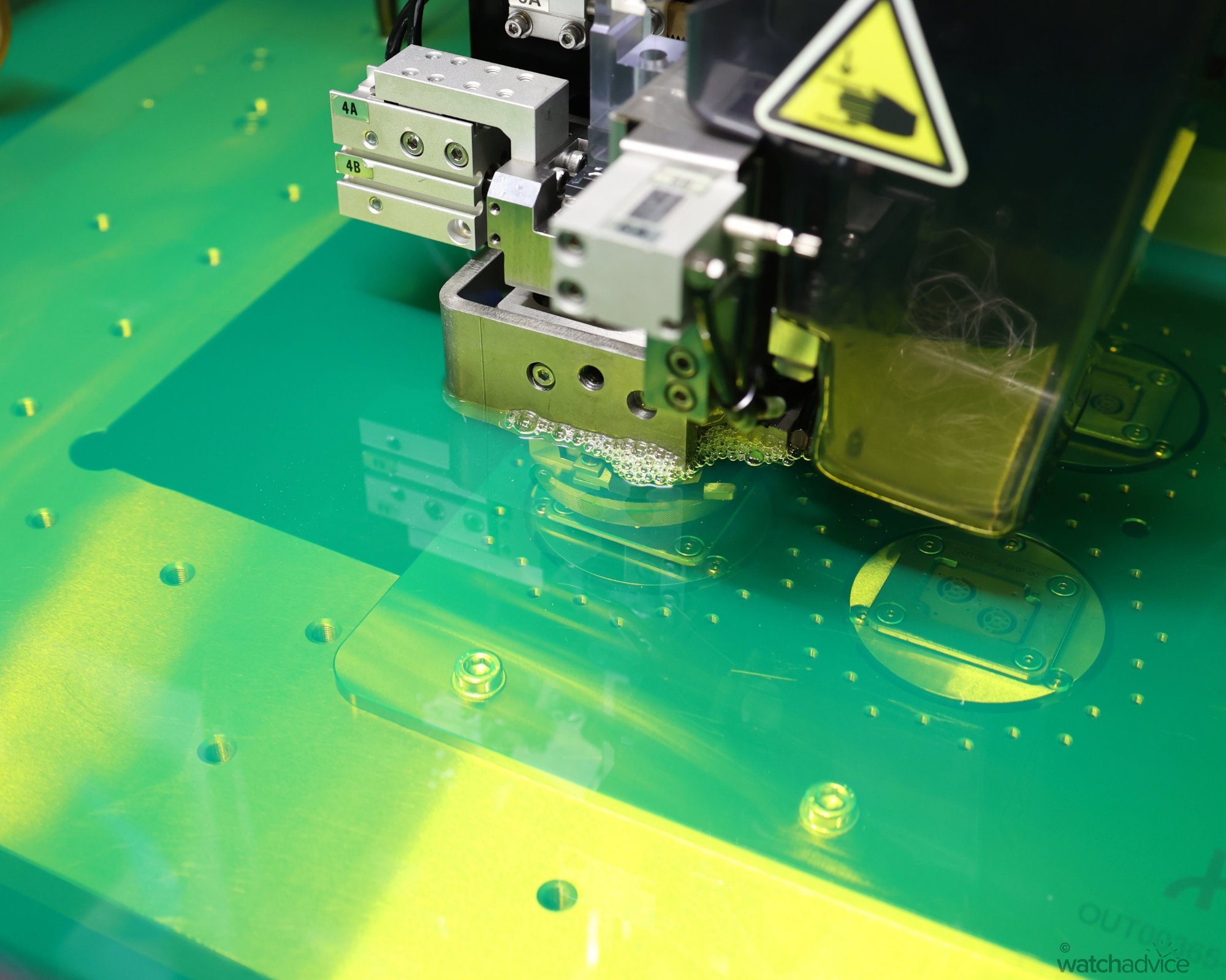

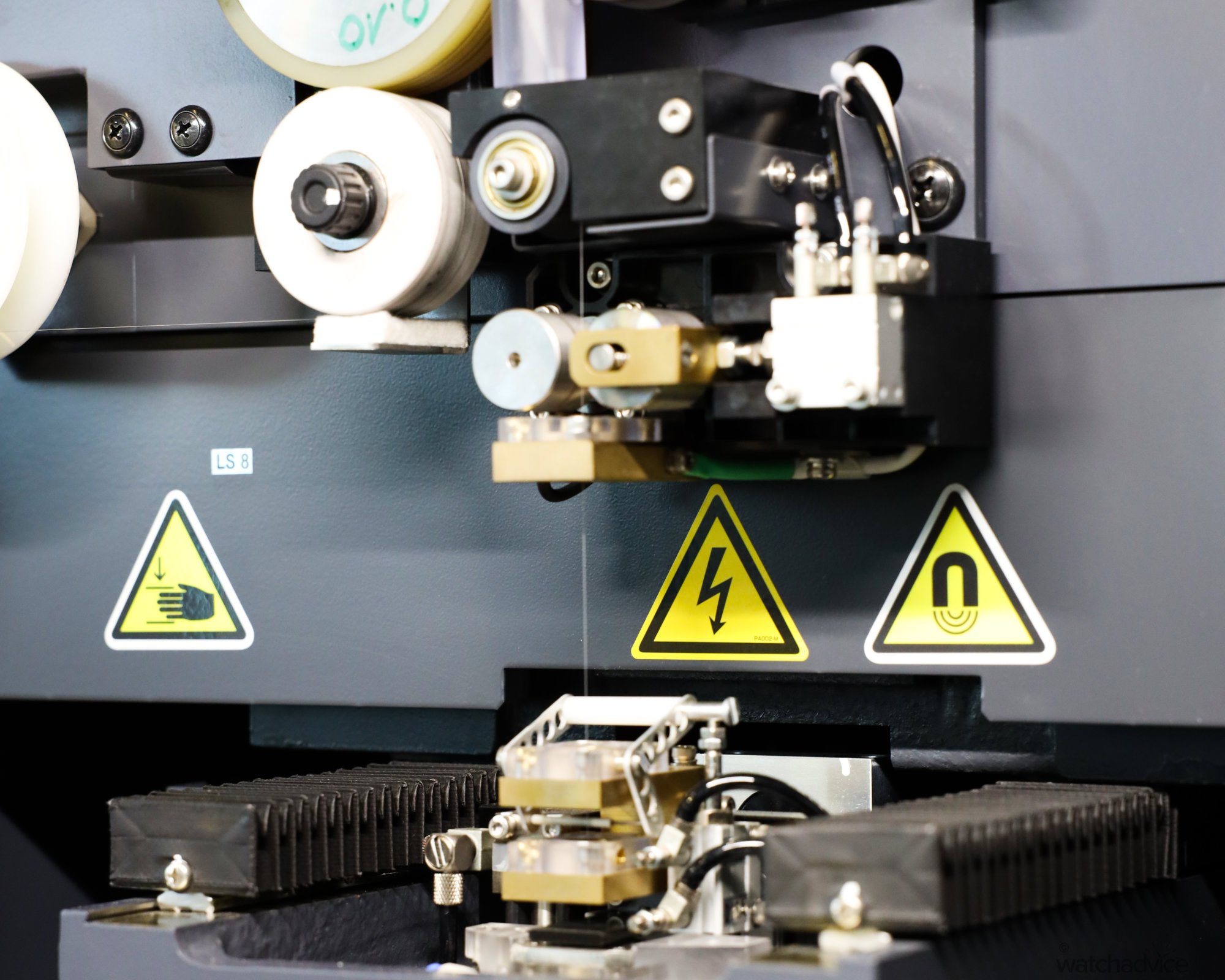

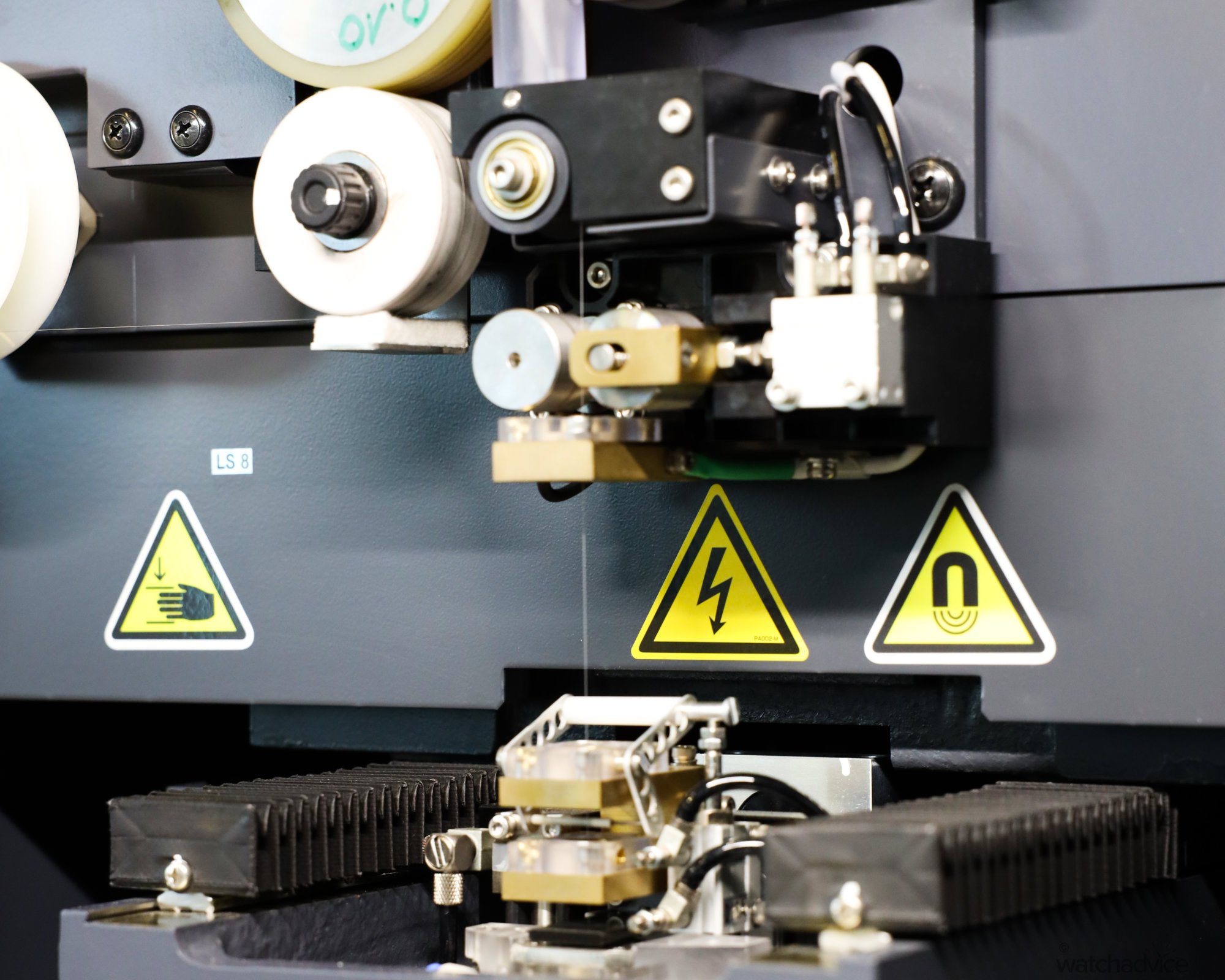

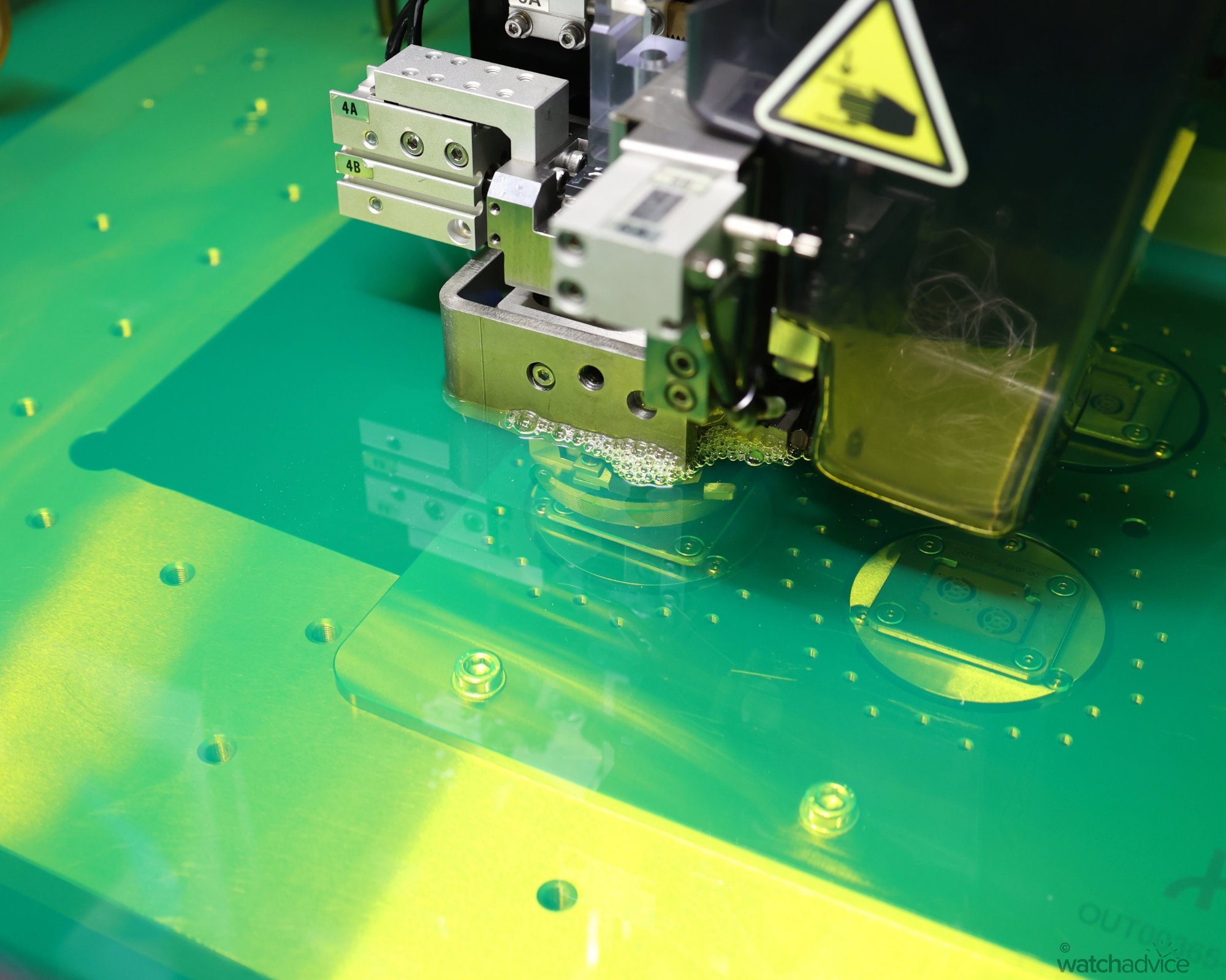

What Hublot does do, is focus its efforts on pieces with movements that are more technical in nature and they can use to showcase their watchmaking prowess. Pieces like the Big Bang Meca-10, their Big Bang Unico Flyback Chronograph, and their special limited edition pieces with their 5-day manual winding tourbillon and their automatic tourbillon movements inside. These are all made in-house at their Manufacture in Nyon, just outside of Geneva, and require the expertise of their watchmakers as well as the specific machines to do the milling and cutting at the start. You can read more about these HERE.

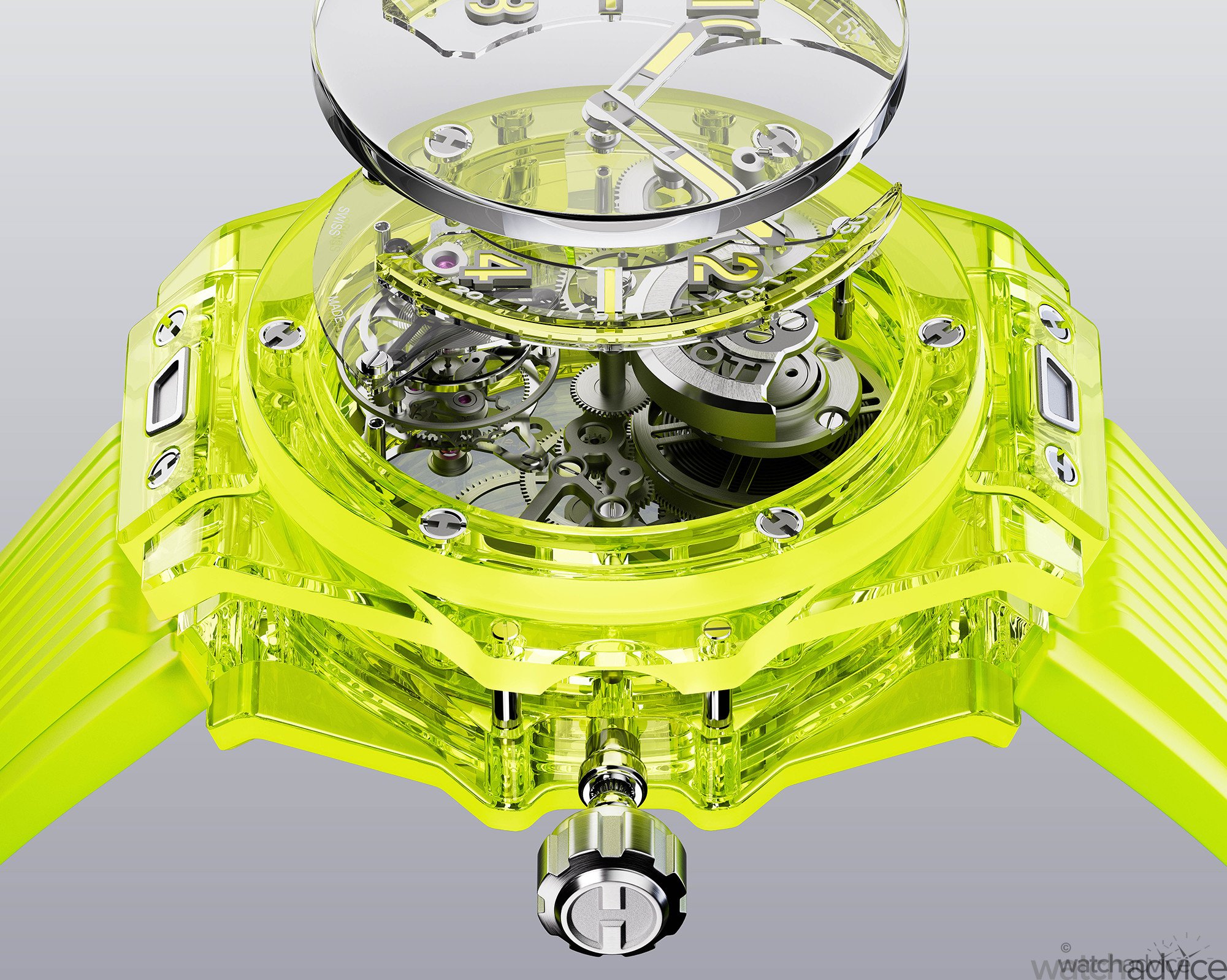

At the start of 2023, Hublot introduced their Big Bang Tourbillon Automatic Neon SAXEM – a piece that was made from a specially design sapphire polymer to enhance the clarity and colour of the neon yellow, something that it in itself took 3 years to develop, but inside was Hublot’s in-house HUB6035 Manufacture automatic tourbillon movement. What makes this movement unique are several factors.

The first is the fully skeletonised movement, which showcases the entire calibre, something that is easier said than done, and unlike other “skeleton” watches on the market, the HUB6035 is a full skeleton movement rather than just being open-worked. Openworked movements still keep a majority of the movement in tact, with key parts of the plates and bridges cut away to show more of the movement, or the dial being skeletonised but the rest of the movement still looks similar. With a fully skeletonised movement, most of the infrastructure has been done away with, only leaving the parts that are needed for it to function and not fall apart. My general rule of thumb is, if you can see your wrist through the watch, it’s fully skeletonised. If not, then it’s open-worked.

Secondly, the movement has been carefully designed to showcase the hero parts of it, namely the tourbillon at 6 o’clock and the barrel with the micro-rotor on top at 12 o’clock. In between, you can view the entire gear train working away to keep time with little to obscure the view right through the watch.

This is just one example of where Hubot excels at creating high-end movements, however, this piece is limited to 50 pieces (all sold) and not one you can just walk in and buy from a boutique. You can purchase the Big Bang Unico and Big Bang Meca-10 watches though, and these two models are where Hublot doubles down on creating great movements for everyday pieces.

Unico

The Big Bang Unico has fast become one of Hublot’s best-selling pieces. Perhaps because it showcases Hublot’s technical capabilities with the materials and the movement, or perhaps because they do look good on the wrist and with most models made from titanium and ceramic, are light and comfortable. I’ve said multiple times over the last couple of years, the flyback chronograph movement that is the HUB1280 is one of the best flyback chronograph movements on the market. It’s both crisp and buttery smooth at the same time, which is exactly what you want when timing. Many others on the market today either have stiff pushers or there is a slight lag when starting it, even though most now use a vertical clutch and column wheel setup.

This is one aspect I mentioned to Samuel Morel, who is Hublot’s Chief Production and Quality Officer, talking to him towards the start of the year. He smiles like a proud dad when I say this, as for him and his team of 200 people working across the entire movement and QC division, the watches are kind of like their babies. You get the same look when talking to the watchmakers as well, even if you’re not speaking the same language (my French isn’t great, let’s say that!), but they have a sense of pride when putting the HUB1280 together.

RELATED READING: Hands On With The Hublot Big Bang Integrated Blue Indigo Ceramic

When designing the Unico movement, Hublot wanted to make a chronograph movement that is both unique (like most things they do) but also robust, reliable, and one that works well. The movement needed to be showcased as well, so it was developed with this in mind and as a result, you can see the open heart of the watch through the dial side, including the column wheel and double coupling system. And via the back, the bridges have been open-worked to show more of the inner workings of the watch, such as the barrel, the balance and more of the gear train.

Meca-10

The Meca-10 is a calibre that is perfect for those that aren’t massively fans of winding a watch every few days (like myself), having a full 10-day power reserve with power reserve indicator to make sure it’s never low on juice. The inspiration for Hublot to create the Meca-10 range began when the designers looked back into their childhood days, when imagination was limitless. As a homage to all those who spent hours designing and building with Meccano, which is a more sophisticated version of Lego Technic that includes plates, wheels, and gears, Hublot created the Meca-10 range.

This movement won the aforementioned Red Dot Award back in 2017, yet another gong for the brand with its innovation in movement design and it is easy to why when you start to delve into the elements of the Meca-10 movement, including the unique slide rack, power reserve indicator and barrel system within the watch.

Looking at the dial side, Hublot has placed a slide rack feature on the 12 o’clock position, which connects to the large wheel at 3 o’clock through the outer teeth on the rack. This large black wheel has six Hublot-type screws and two larger-shaped holes to assist with the power reserve indicator. It also has two sets of teeth on opposite sides, one of which connects to the 12 o’clock rack position and the other which connects to the 6 o’clock “Power Reserve” indicator wheel showing the 10-days worth of power. Once the reserve counts down to 3 days, one of the large holes on the large black wheel starts to turn red, indicating to the user that the watch needs to be wound.

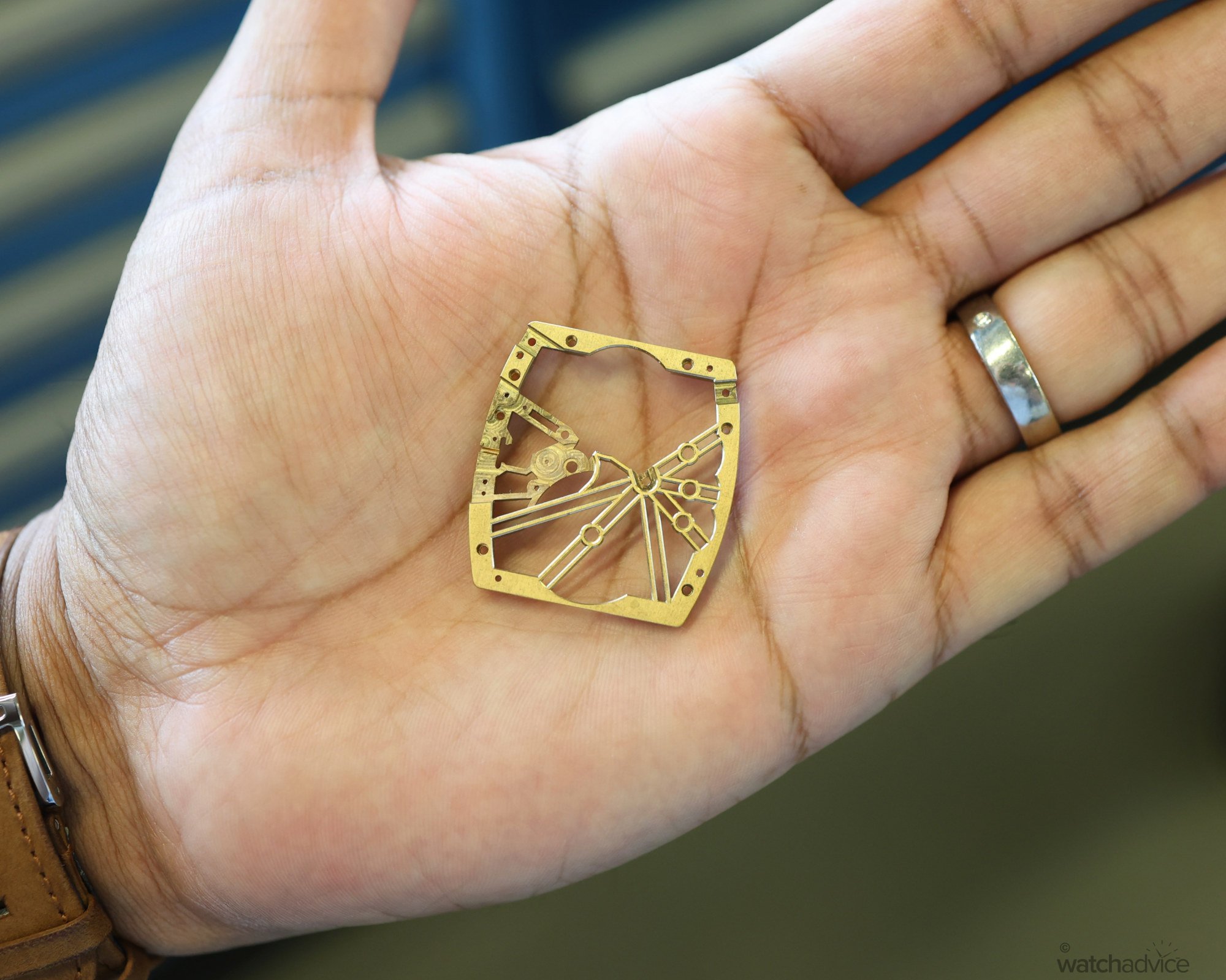

Viewing the Meca-10 from the reverse side, Hublot has employed a three-bridge system (see where the Meccano inspiration materialises here?) as part of its skeletonisation to hold the main components in place, including the two large barrels that deliver the 10-days worth of power to the escapement. This is yet another example of where Hublot took it’s time to develop this – over 2 years in fact to conceptualise, design, and manufacture it to what you see today. This is also a pure example of what Ricardo Guadalupe talks about when he says he is focused on quality, not quantity when it comes to their in-house calibres.

Closing Thoughts

Having spent some time delving into both Hublot as a brand, as well as their movements which includes visiting and exploring their Nyon Manufacture, I can say it’s been an educational journey, to say the least. Not only have we spoken to some of the key people in charge of moving Hublot forward, such as CEO Ricardo Guadalupe, Chief Production and Quality Officer, Samuel Morel, and Materials Engineer for Hublot R&D, Roberto Valsangiacomo, but we’ve spoken to some of the people that are involved at different stages of production of the watches – the people who are actually at the ground level and responsible for literally bringing these movements to life.

When you go down the Hublot rabbit hole, you start to uncover what the brand is about, the DNA that runs through the business and people who work for it, and the vision that Ricardo has for it. A big part of this is the material science Hublot engages in with their cases, sometimes taking years to develop new materials, or colours, the other element is the focus on their Manufacture Calibres that are at the forefront of technical engineering.

Hublot is a luxury sports watch brand that has set itself apart from other more traditional watchmakers thanks to its drive to design and develop movements that push the limit of what is possible. This coupled with their innovation in material sciences makes them a very different watchmaker with a different value proposition to others – you buy a Hublot for its designs, artistic collaborations, and in the case of their MP collections, Limited Editions, Unico, and Meca-10 pieces, the movements that have spent years in development to make them highly unique. When you look at the Classic Fusion Orlinski editions below, this is all the above in one piece. Artistic design, vibrant ceramic colours which is not easy to do, and a highly technical in-house skeletonised tourbillon movement with 105 hours of power reserve.

Once the new building is finished in 2026, it will be very interesting to see how Hublot adapts this current philosophy to other movements and where they will take these. We’ve already seen examples of how they can push the boundaries of skeletonisation with the Classic Fusion movements inside the Classic Fusion Orlinski, another one of their in-house movements with the HUB6021 manually wound tourbillon movement and 105-hour power reserve. I’d go out on a limb here and say that their Spirit Of Big Bang collection could be one of the first to have a re-designed Manufacture Hublot movement once this facility is up and running, possibly a tonneau-shaped version of their current Unico HUB1280 cailbre? Time will tell, let the journey continue!

This article was written as part of a commercial partnership with Hublot. Watch Advice has commercial partners that work with us, however, we will never alter our editorial opinion on these pieces, a fact that is clearly communicated to the brands when entering into a commercial arrangement. At Watch Advice, we categorically do not sell outcomes or our editorial integrity. We will never say a watch is good when it’s not.

Photo Gallery