Switzerland has been the heart of fine watchmaking since the 19th century. When we think of the best of the best in haute horology, we turn to brands like Vacheron Constantin, Patek Phillipe and Audemars Piguet; the holy trinity of Swiss watchmaking. Traditionally these brands have been known for their high level of finishing, time keeping and complication of their timepieces.

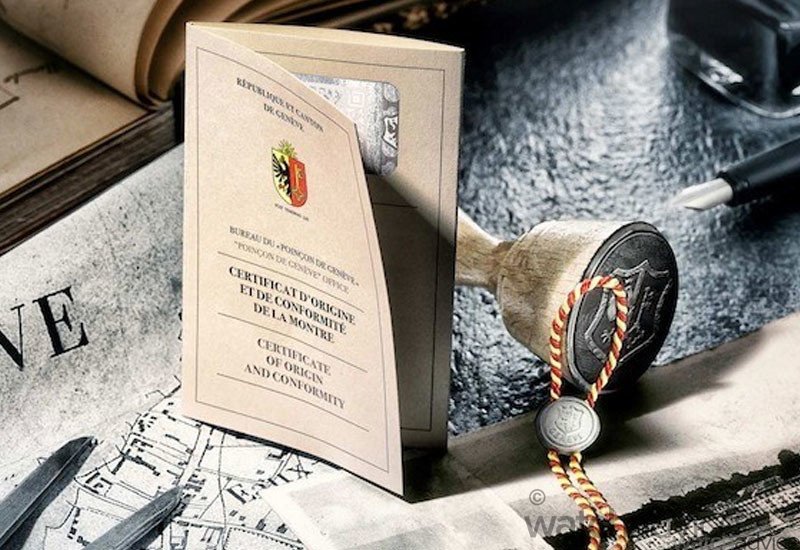

In order to maintain the mystique and indeed, the prowess of fine watchmaking, the Canton of Geneva developed the Poinçon de Genève, the Geneva seal.

The Genevea seal is a certification reserved for only the highest quality time pieces hailing from the city of Geneva, the traditional home of swiss watchmaking. So highly regarded is the watch industry within Geneva, laws have been enacted to maintain high standards across the industry.

In order for a watch to be eligible for the Geneva seal, it must meet some of the strictest standards within the industry.

Firstly, the manufacturer of the watch must be registered in Geneva. The manufacturer itself must also have carried out the assembly, adjustment and casing of the movement itself. There are no ring in ETA movements in use here, only manufacture movements need apply.

Secondly, all elements of the timepiece must be submitted to and approved by the technical committee of the Poinçon de Genève. This means that every screw, every millimetre of material that goes into the construction of the watch, must be planned out and approved before the brand so much as sets a hand to a dial, in order to be eligible for the Geneva seal.

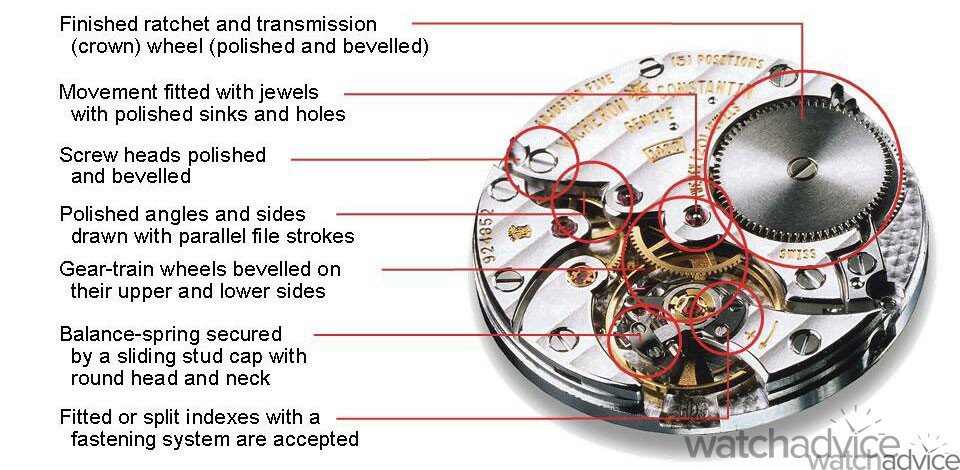

The technical requirements to have components approved are also some of the most stringent in the world. The Geneva seal is a certification focussed on the heritage of Swiss watchmaking, the committee hellbent on keeping those traditions alive dictate the following.

The entire movement must be jewelled with rubies set in polished holes. These jewels and holes must be olive drilled, a technique whereby the jewel is cut, bevelled and rounded at the top and bottom in order to create a reservoir for lubricants.

The wheels of the drivetrain must be chamfered and polished to perfection. The hairspring must be cut from a single sheet of steel and then polished and chamfered, an exercise that only the highest level of watchmaker can complete.

Finally, the Geneva seal is a test of the entire watch. As such, the finished product must comply with all of the standards, it must meet its stated water resistance, power reserve rating and of course time keeping standards.

Once the watch passes certification, the movement can be stamped and numbered with the Geneva seal, and since 2012, the case of the watch will also bear the stamp.

If you are purchasing a watch that bears the seal of Geneva, you can be absolutely assured that it is of the highest quality. The standards set by the Canton of Geneva are substantially more difficult to achieve than basic chronometer or even master chronometer certifications.