Cartier has had a resurgence of late among the watch community, and we visited their Manufacture in La Chaux-de-Fonds to see how they create their timeless pieces.

This article is written in collaboration with Cartier

Just under 2 hours outside of Gevena in the canton of Neuchâtel is a picturesque town called La Chaux-de-Fonds. The name may sound familiar as this is where many Swiss Watch Manufactures are located. Nestled in the valley with mountains in the background and rolling hills in the foreground, this region paints an almost watercolour backdrop for the art of watchmaking. Yes, this may sound a little corny, or overexaggerated, but this is exactly what we found when we visited the Cartier Manufacture this year. I would be lying to say the thought of packing up and moving there never crossed my mind.

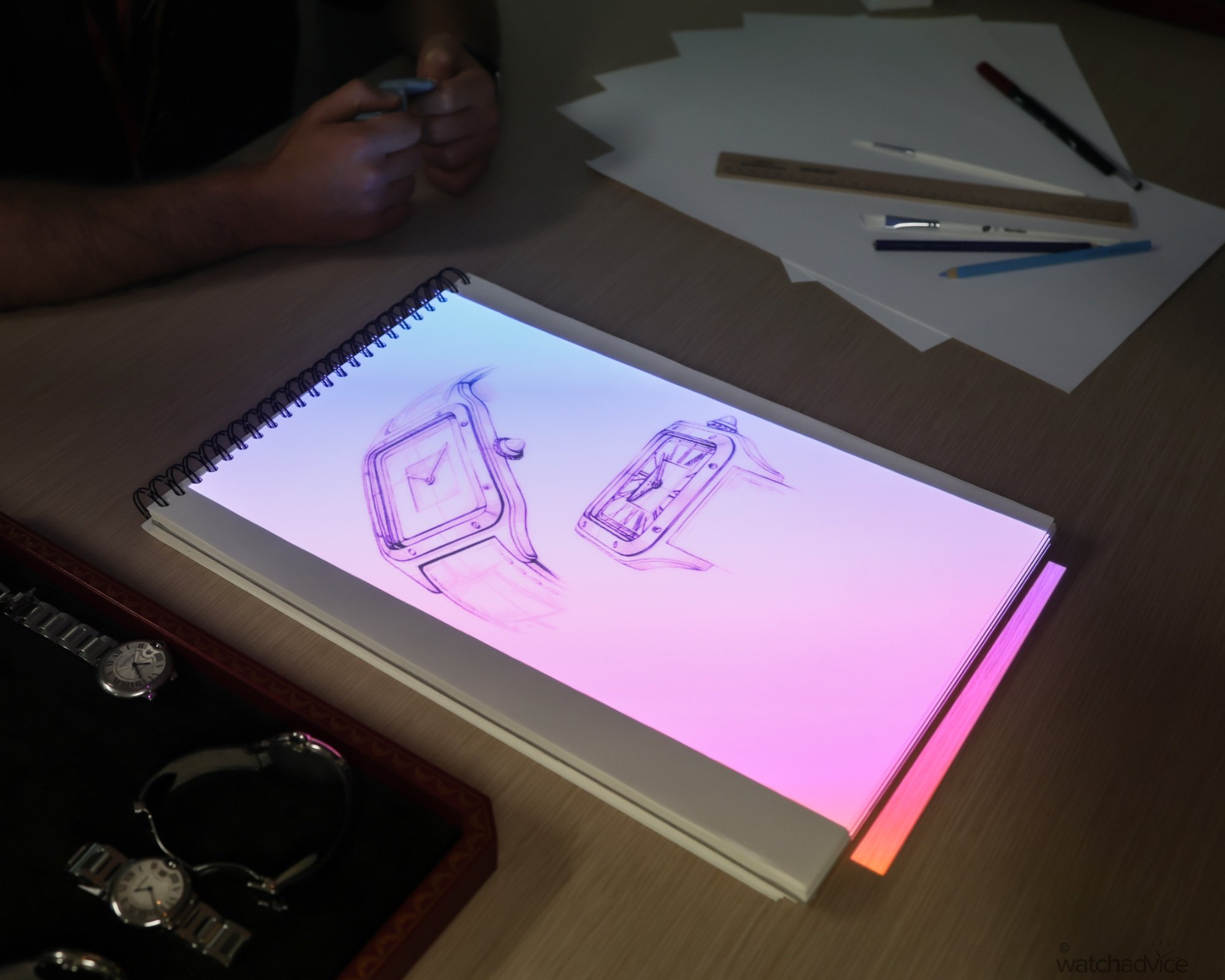

It’s an appropriate setting for a Maison such as Cartier to have its home here as it feels quite serene and a perfect place to design and create pieces of art for your wrist, which now knowing what I know about Cartier, is very much core to the brand’s DNA, both with their case shapes that are recognisable around the world, to their in-house movements that power these pieces, some pieces of art in their own right.

RELATED READING: The Santos Stories – A Brief History Of The Iconic Watch

The Manufacture

Unlike other Manufactures, Cartier does not often do tours or visits. In fact, they reserve this now for media and industry people only one week of the year, during Watches & Wonders, and outside of this, you need to be very, very VIP to get a look inside. This has been done mostly for the benefit of the employees here. Imagine going to work at your office or workplace and having people come through every day on tours, stopping you in the middle of a task that requires a lot of concentration and asking you questions about what you’re doing. Sounds fun right? Thinking about this, it would get a little frustrating after about the first week. So kudos to Cartier in this respect for putting its employee’s needs before publicity. It’s a rare thing in this day and age.

Entering the Manufacture, you quickly realise that unlike the other watch Manufactures, Cartier has evolved over the years, adapting to the times and making sure they both stick to what they do well, as well as making small incremental improvements to their processes. While you may think this would be the case with many brands, and in other industries as well, I can tell you from personal experience this isn’t always the case. It’s hard to imagine when looking at the main building that this once was a small operation as part of the burgeoning cottage industry that once was Swiss watchmaking. Today, it is a much grander operation, but once inside and into the main areas where Cartier designs and makes their watches, it is very much down to business.

What stuck out to me was how Cartier sticks to what they do so well. They are an artisanal brand, and one with a rich heritage of hand-crafted watches. As such, what impressed me is that Cartier has refined and honed in on what makes it the second-largest watch brand in the world today – their timeless designs and attention to craftsmanship and detail, all with a human touch.

Where Machines & Humans Meet

Walking through the case manufacturing area, you can pick out all the iconic cases being milled and then refined by both hand and machine. Like all Maisons, the cases are all milled in specialised machines that will cut and shape the metal into the shape of the case. This is then refined by hand and, finally polished by individual experts who have spent years refining their skill in perfectly polishing the cases on the polishing wheels, all by touch and sight.

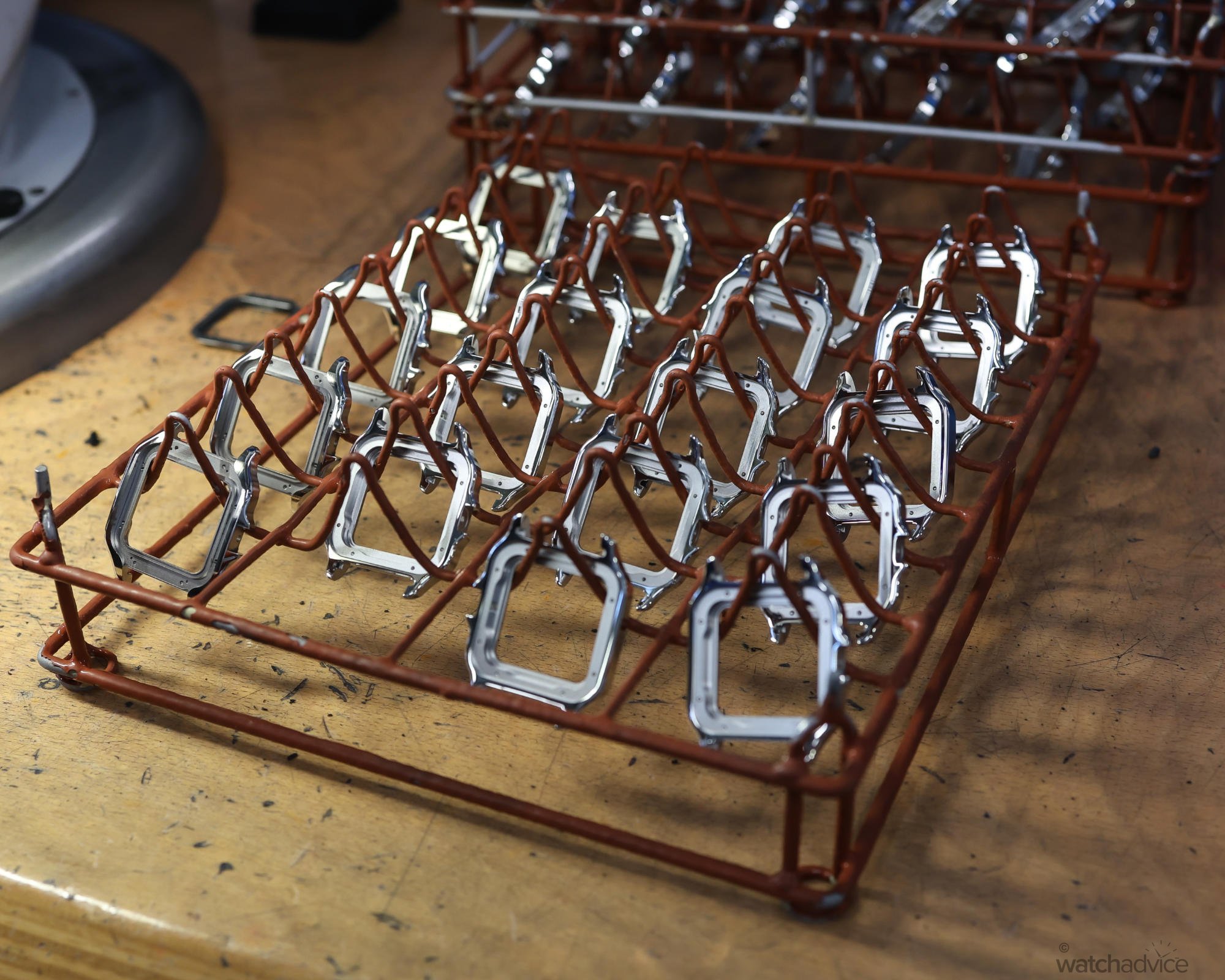

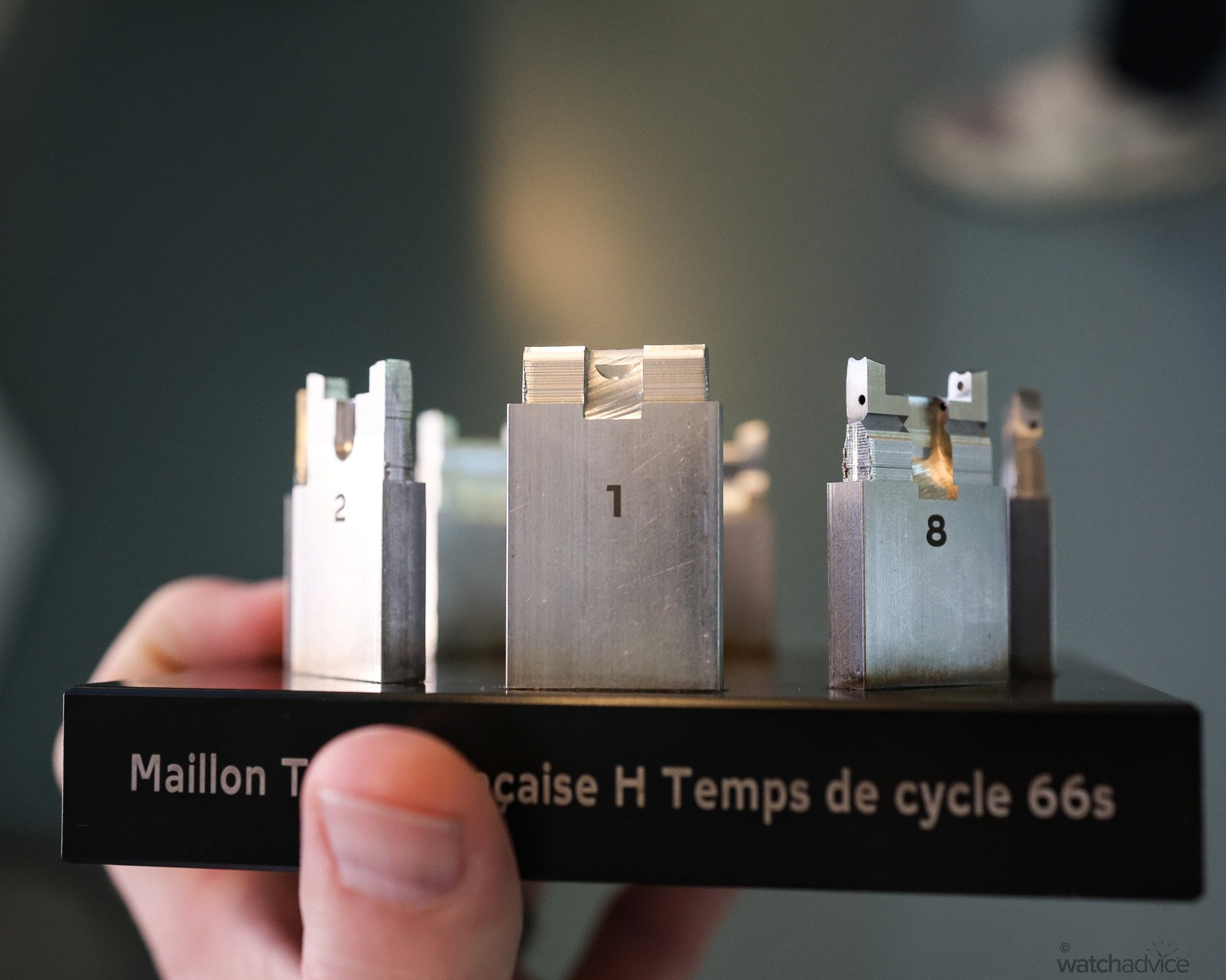

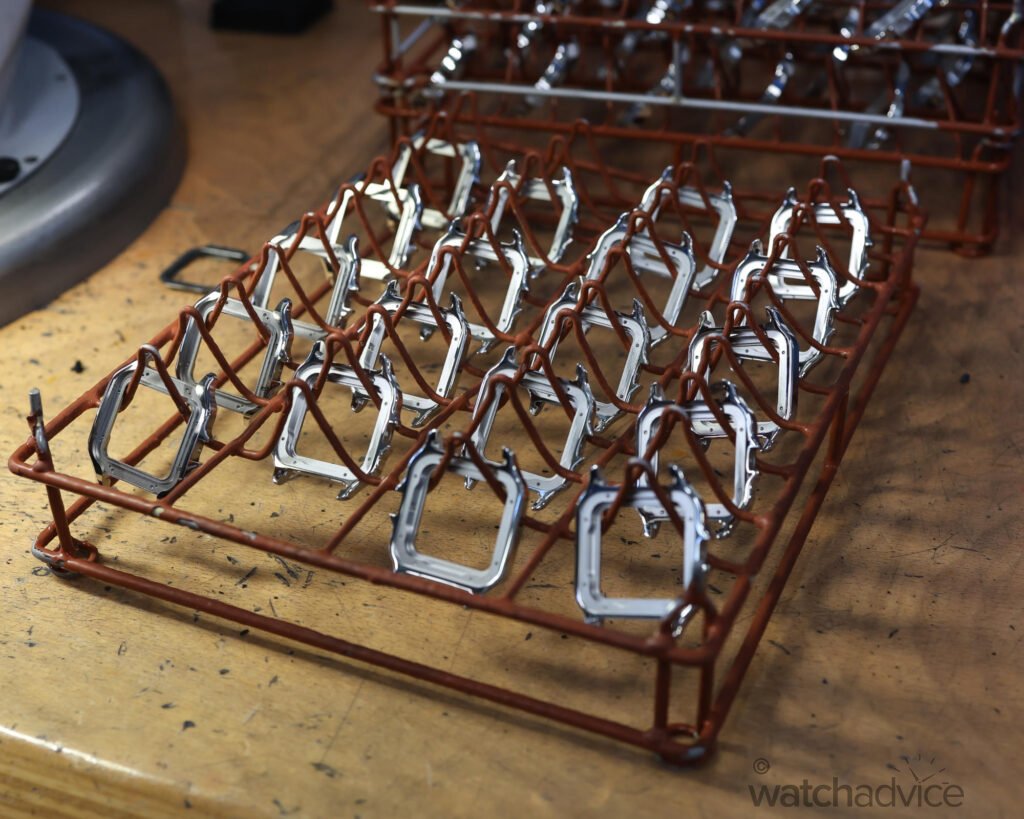

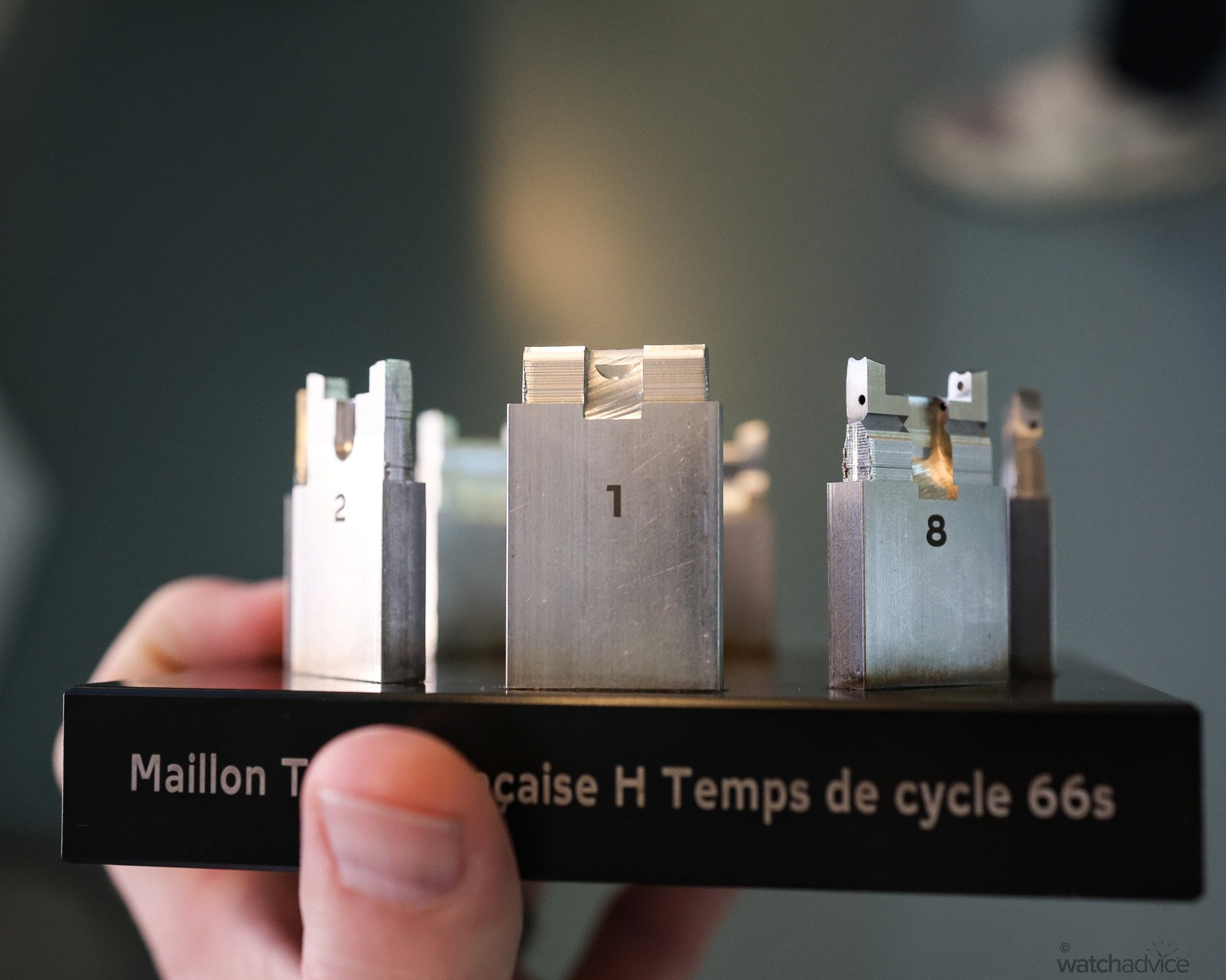

Continuing on, we visit where the bracelets are milled and then taken to the workshop to be assembled. Below, you can see the different stages of the milling and cutting Cartier undertakes on the links for its bracelets. In all, there are 8 stages that a single link will undergo to get it to an almost finished stage. Image One is the first cut to get the rough shape, shown on the piece of steel numbered “1”. Then as the steel is worked through each stage, it gets closer and closer to the final stage, which you can see in Image Two with the piece of steel with the number 8 on it.

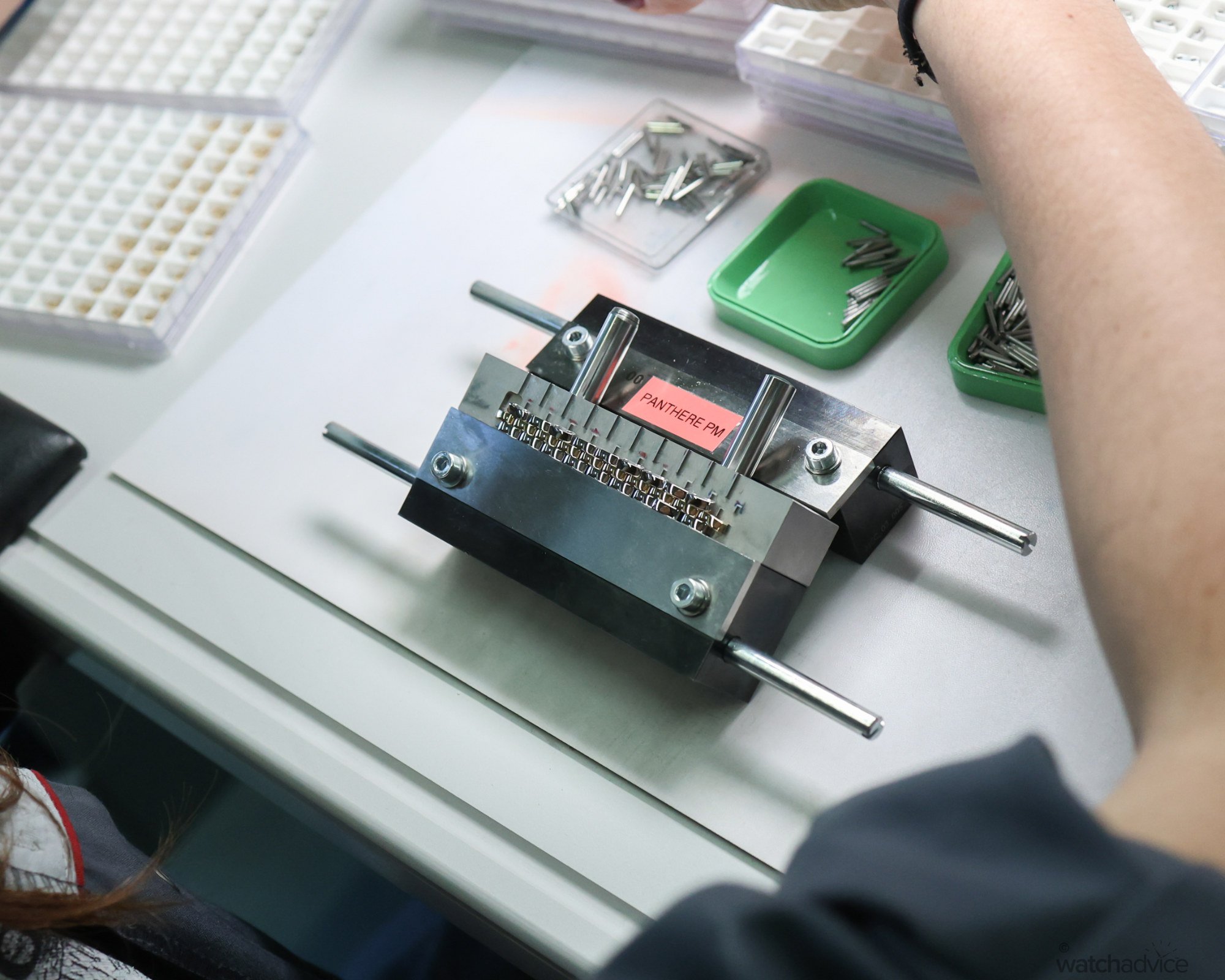

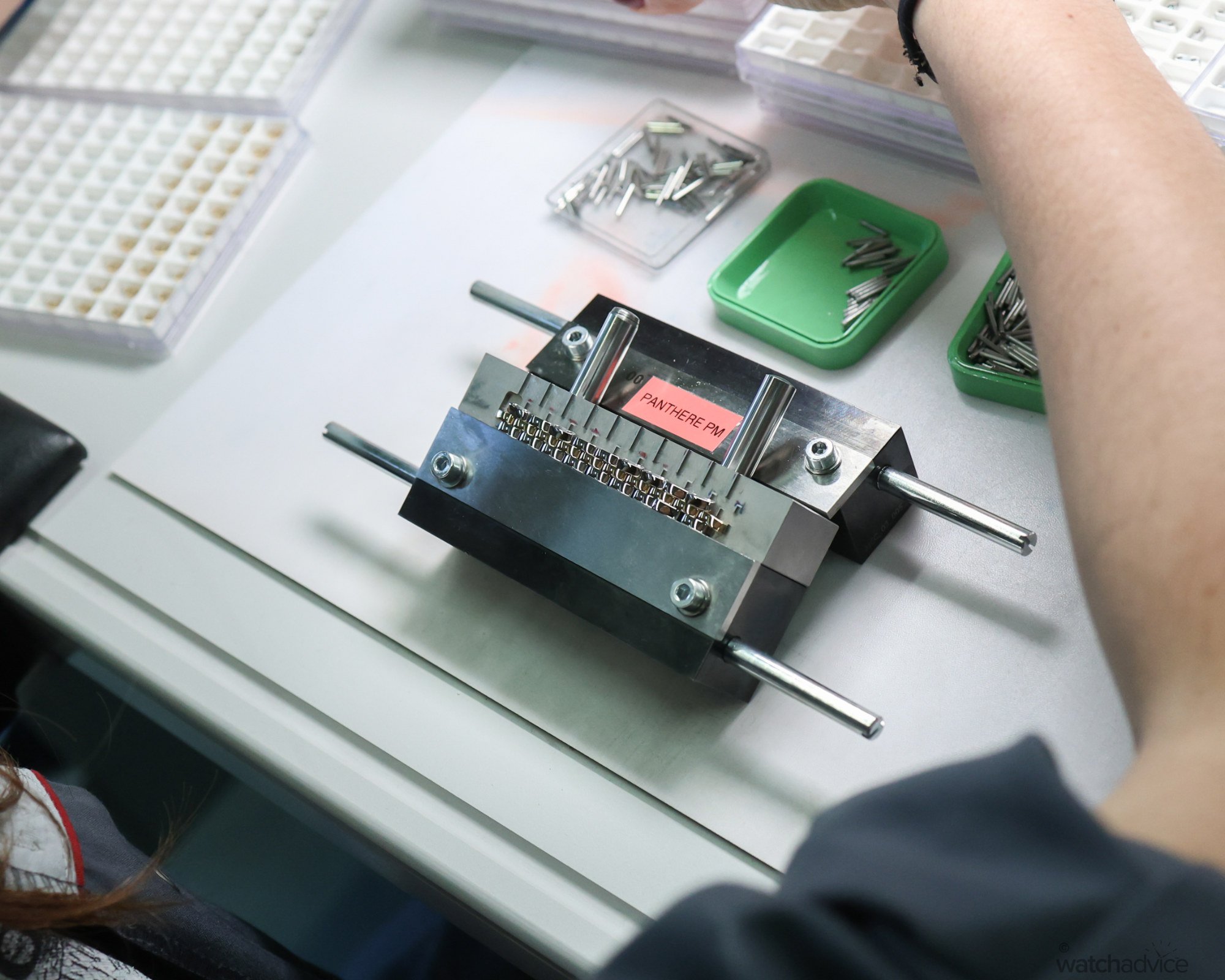

The one area that took me by surprise was the assembly area for the bracelets. Up until this point, I had not considered how bracelets, in general, are assembled (or put a lot of thought into it for that matter – it’s not one of those things that keep me up at night). When you see the watchmakers sitting in their chairs, with all the small links of a Panthère bracelet in front of them, and one by one, they are sliding these into place and joining each and every link up with the pins in place it hits you. Yes, these are again all put together by hand. What also amazes me is the speed at which they do it. Standing there watching them and talking to them, they assemble an entire two-tone Panthère bracelet by hand, and what amounts to maybe 5 minutes with them engaged in conversation with us. It is second nature to them now, something you can tell they take immense pride in.

RELATED READING: Hands On With The Santos de Cartier

The Human Touch

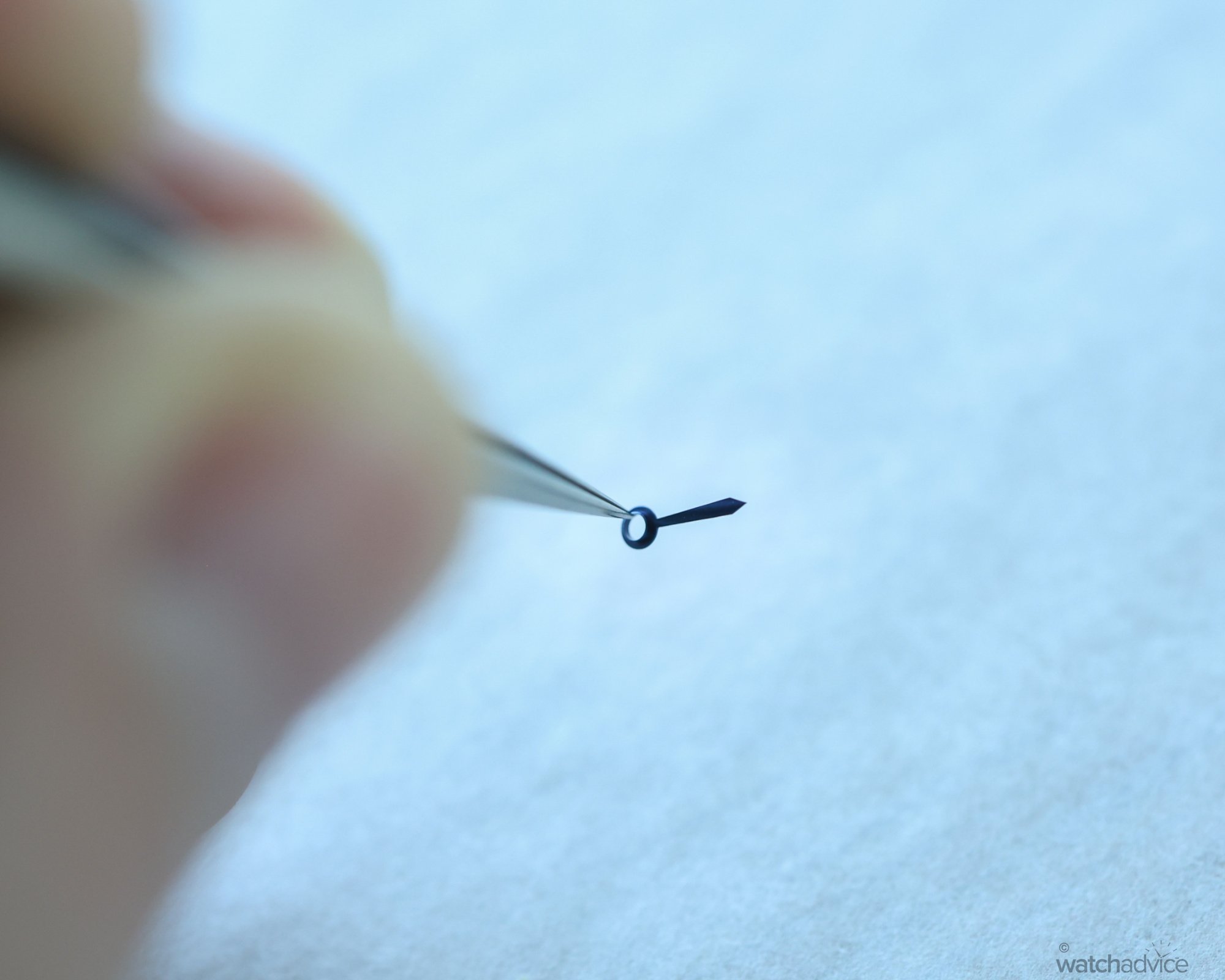

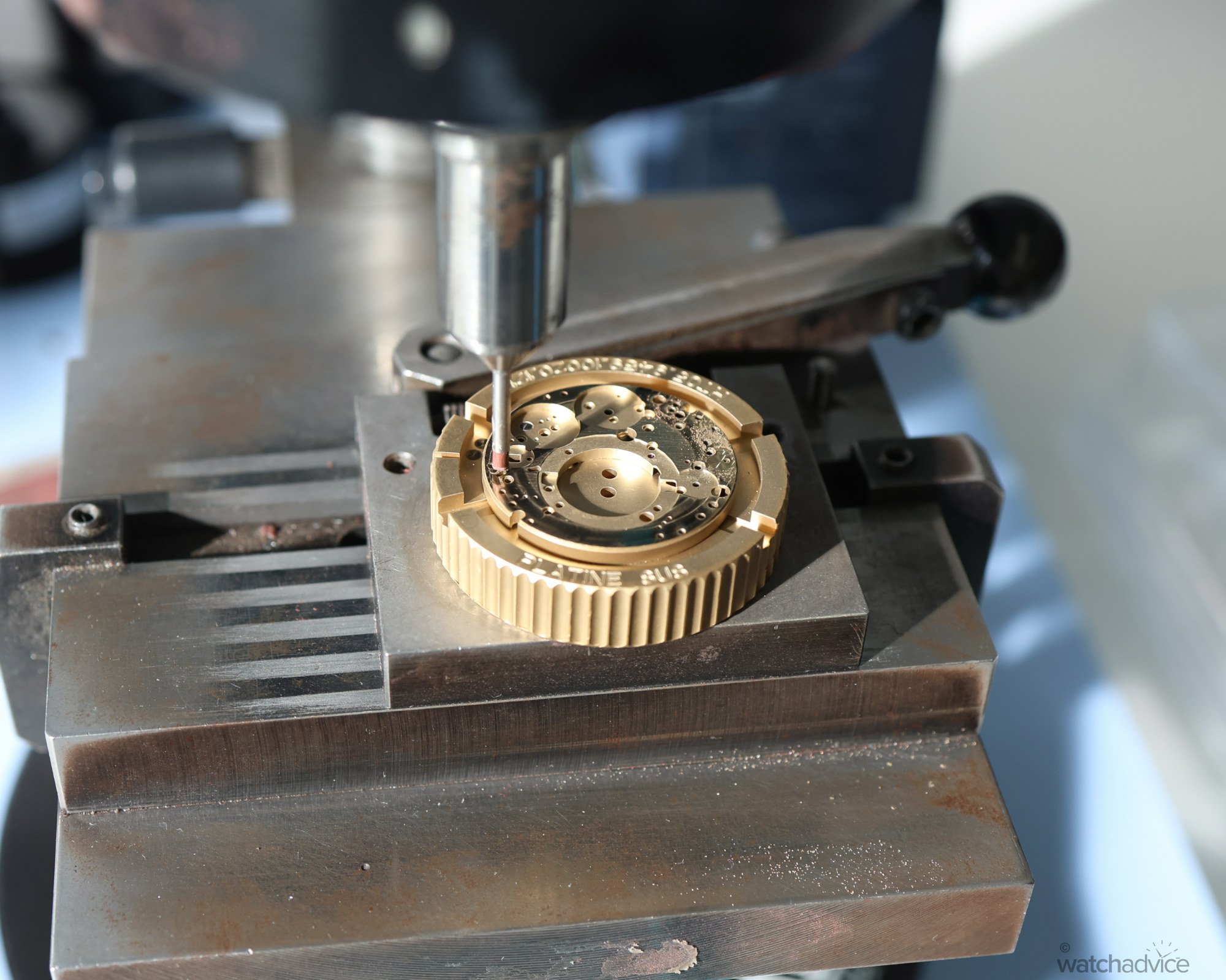

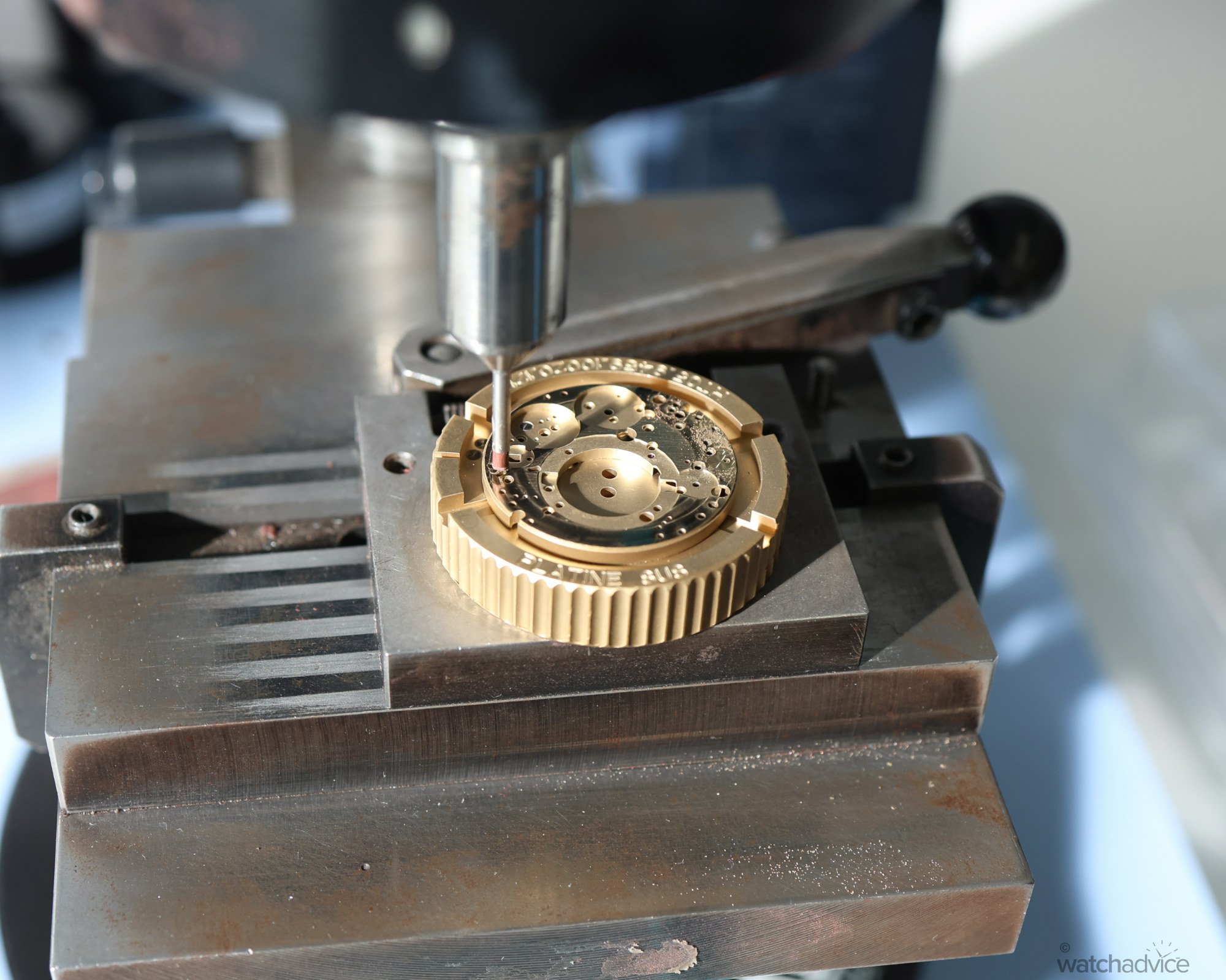

Moving on to the movement assembly, we find many watchmakers going about their business uninterrupted (until we walked through that is), putting the movements, hands, and dials on the watches, many instantly recognisable. The same level of skill and expertise is applied here, just like the case and bracelets we had witnessed earlier. You can see in the images below one of the watchmakers putting the finishing touches on the movement, and then preparing the dial of the Cloche de Cartier.

When you consider the size of the pieces that go into a watch movement, especially one such as the Cloche de Cartier, I’m always amazed at just how steady a hand you have to have, not to mention the patience of picking up each element and placing it where it needs to go – in many cases, a very small component into a very small place.

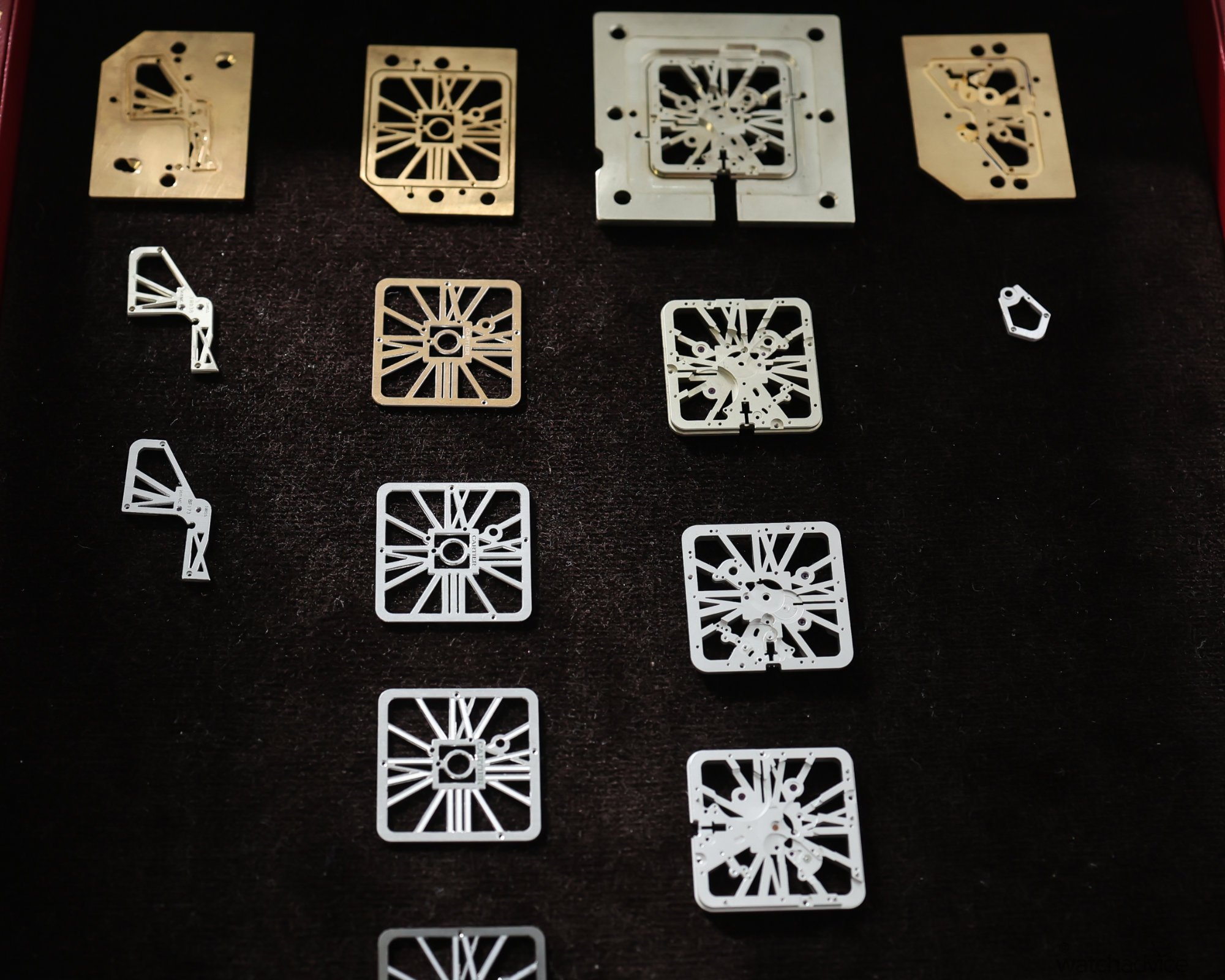

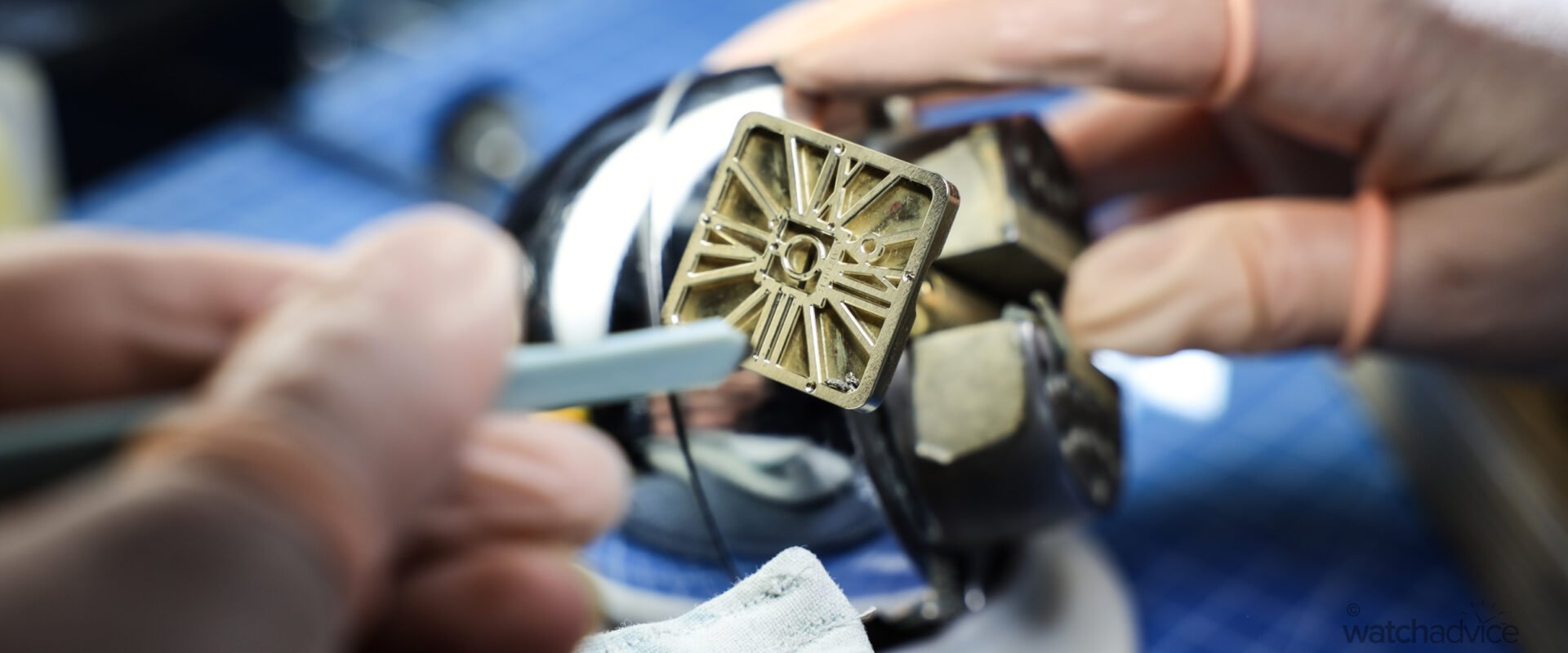

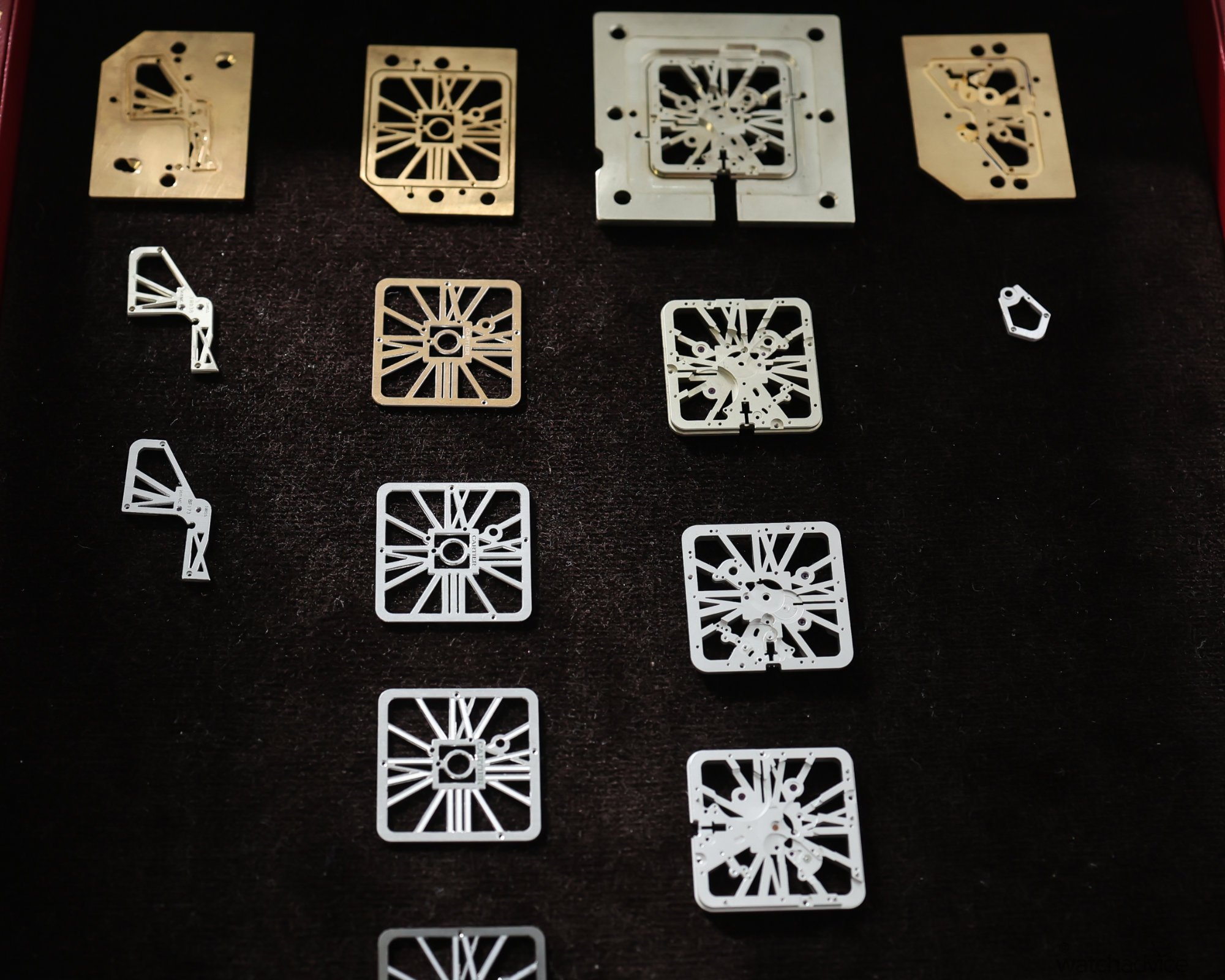

We were also fortunate enough to spend a little time with the people who work on the skeleton dials and movements and were able to see this process in more detail. Once the main components have been cut and semi-refined in the cutting machines, they are then sent here. Using small manual and electric tools, the people craft the movements and dials with care, ensuring their finish is perfect and ready to be placed in their new home within the selected pieces.

As you can see from the above, the first image showcases the stages of the skeletonised elements of a Santos dial and movement, with the dial side facing components on the left, and the bridges and plates that sit under this on the right. These are cut from the base steel or gold, and then the watchmakers, which can be seen in the next two images refine and polish these to where they are ready to be put into the movement and watch itself.

The people at Cartier were kind enough to let us have a try at some of the detailing that goes into their pieces, and even though I’ve done this before, it is always fun to see if you’ve improved or if pearlage is still as difficult as ever! Hint, it’s the latter!

Quality Control

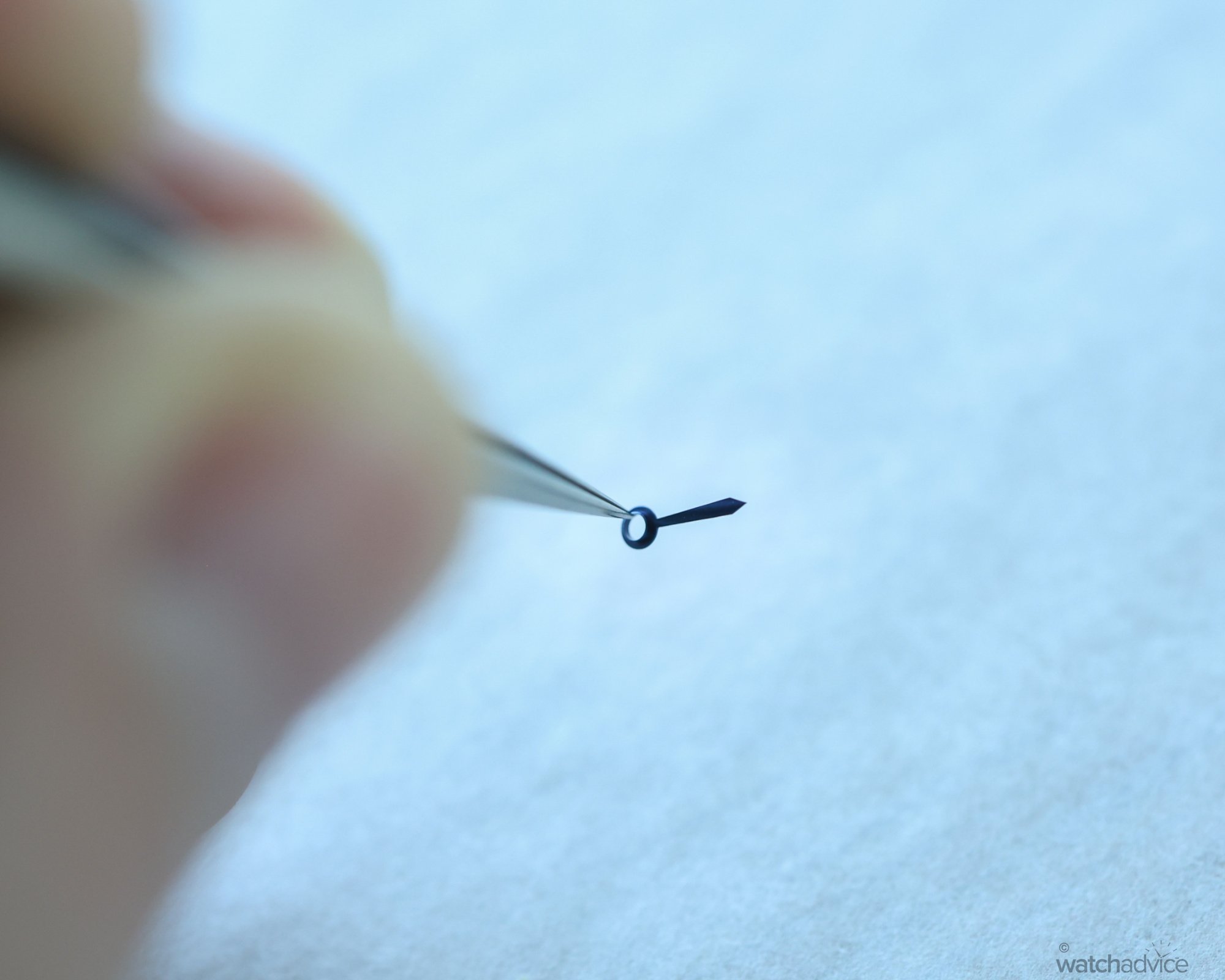

Quality Control (QC) is also paramount at Cartier. As you can see in this image, one of the workers is inspecting the Blue Fired hands one by one. If the hand isn’t up to the quality it should, it is placed into the clear container and sent back. This is all done by hand, and by looking at them through a loupe. It isn’t a machine doing this, it is this lady right here, each and every day!

We had a bit of a play with the hands themselves (see images below), just to put into perspective how fiddly it is to pick up the hands, and then look at them under the loupe for defects or errors. Just to pick them up out of a small bowl was a challenge, let alone sitting there and moving each individual one around to see if they were defect-free.

Artisans At Work

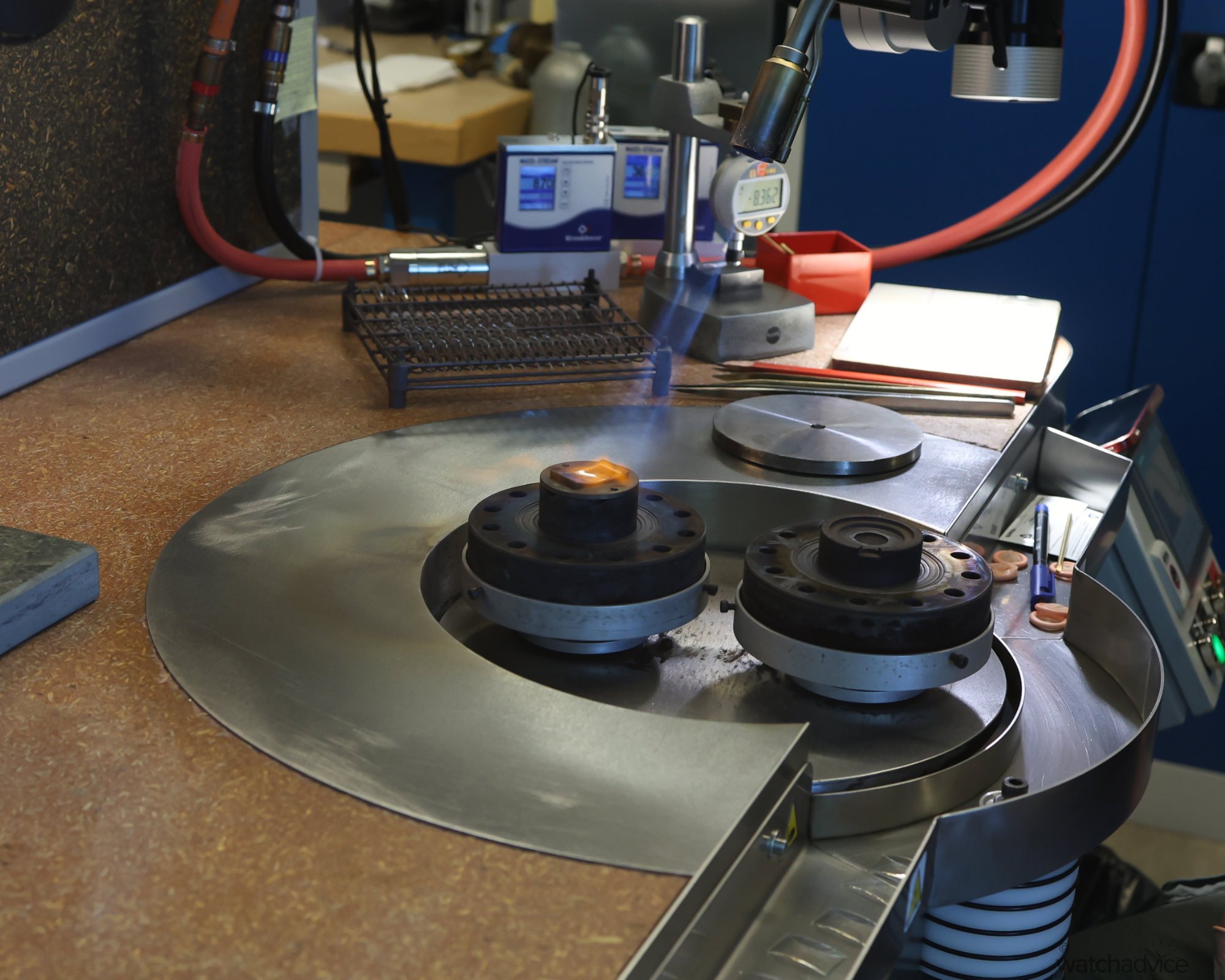

Cartier prides itself on its craftsmanship. As I alluded to previously, many of these pieces are all assembled by hand, and many of the components that make up a Cartier timepiece are crafted by individuals at their La Chaux-de-Fonds Manufacture. The one area I was keen to see was their crystal making and shaping. When Cartier brought out their 2023 Privé collection, specifically the Cartier Tank Normale, we were amazed to find out that the faceted crystal on this piece is shaped entirely by hand-firing the crystal to the exact shape and proportions. This is done by one gentleman at Cartier, and thankfully there is a succession plan in place! This highly specialised skill is one that very few people in the world possess, so it makes these pieces even more special.

RELATED READING: Cartier & Watch Advice Showcase 2023 Novelties

Cartier is known for their variety of case shapes, and as such, their crystals also need to be as varied. From the misshaped Crash to the oval Baignoire, to Cloche to Ballon Blue with the small indent at 3 o’clock to account for the crown, all have crystals that require more effort to shape them than traditional circular crystals. But it is not just the Tank Normale that gets this treatment.

All of the above crystals are made in Cartier’s specially designed lab, where they are fired and shaped by an individual who meticulously turns and moves them to get each one shaped perfectly – ready for the piece it is intended to be placed in. Like a master glass-blower, the gentleman we observed doing this did so with seeming ease, but this is a skill that has been honed for many, many years, and is not to be taken for granted by us onlookers.

Finishing up our visit to the main part of the Manufacture, having seen all the different movements, cases, bracelets, and crystals being made, assembled, and finished, we went on to the next section, which is where Cartier does all their quality tests on the watches themselves. Earlier in the article, I mentioned the Quality Control on the components as they were being made, but the key to Cartier’s quality and durability is in both the design stages, and then testing the final prototypes for ‘life events’ or just plain everyday use.

Durability & Testing

The one thing a watch should be is durable. It should be able to stand up to the harshness that can be everyday life from small bumps and knocks to magnetic fields that are now all around us and inescapable thanks to modern technology. Unfortunately, some brands don’t see this as an issue, and you need to wear them with bubble wrap. Cartier on the other hand places a massive emphasis on this – making sure their pieces withstand everything that life throws at them, or us for that matter. Knowing this, Cartier watches and movements are put through a series of tests to ensure their durability and accuracy.

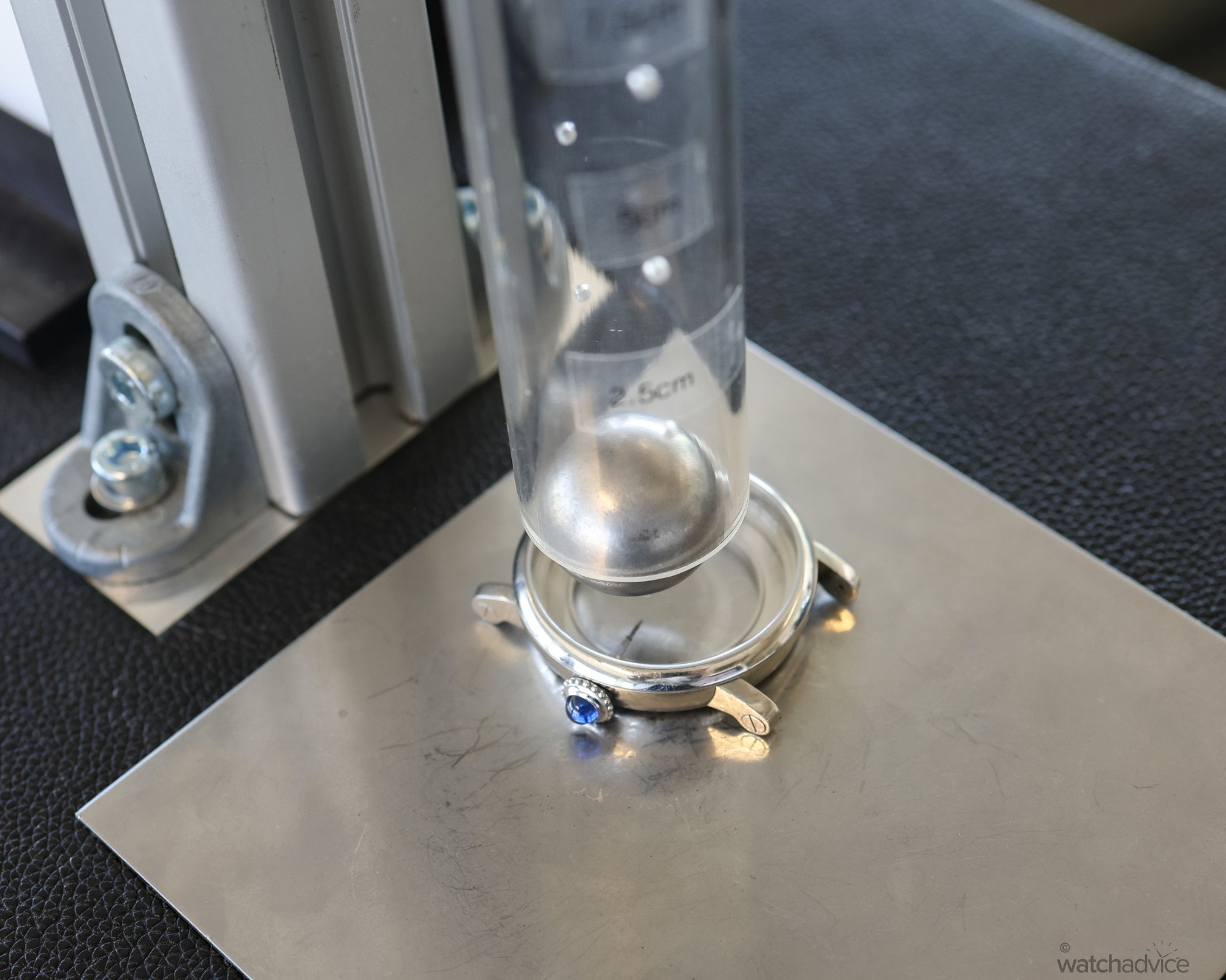

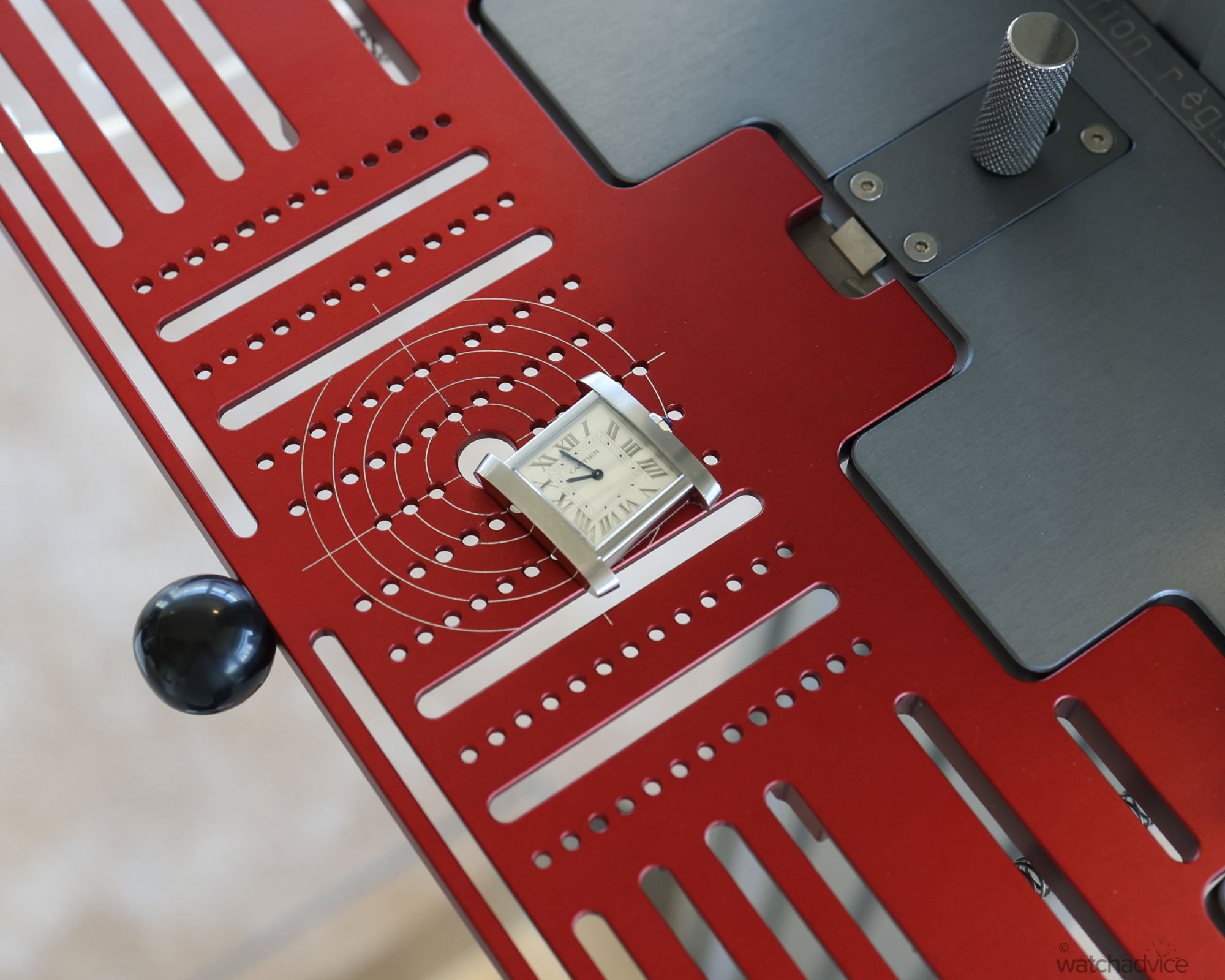

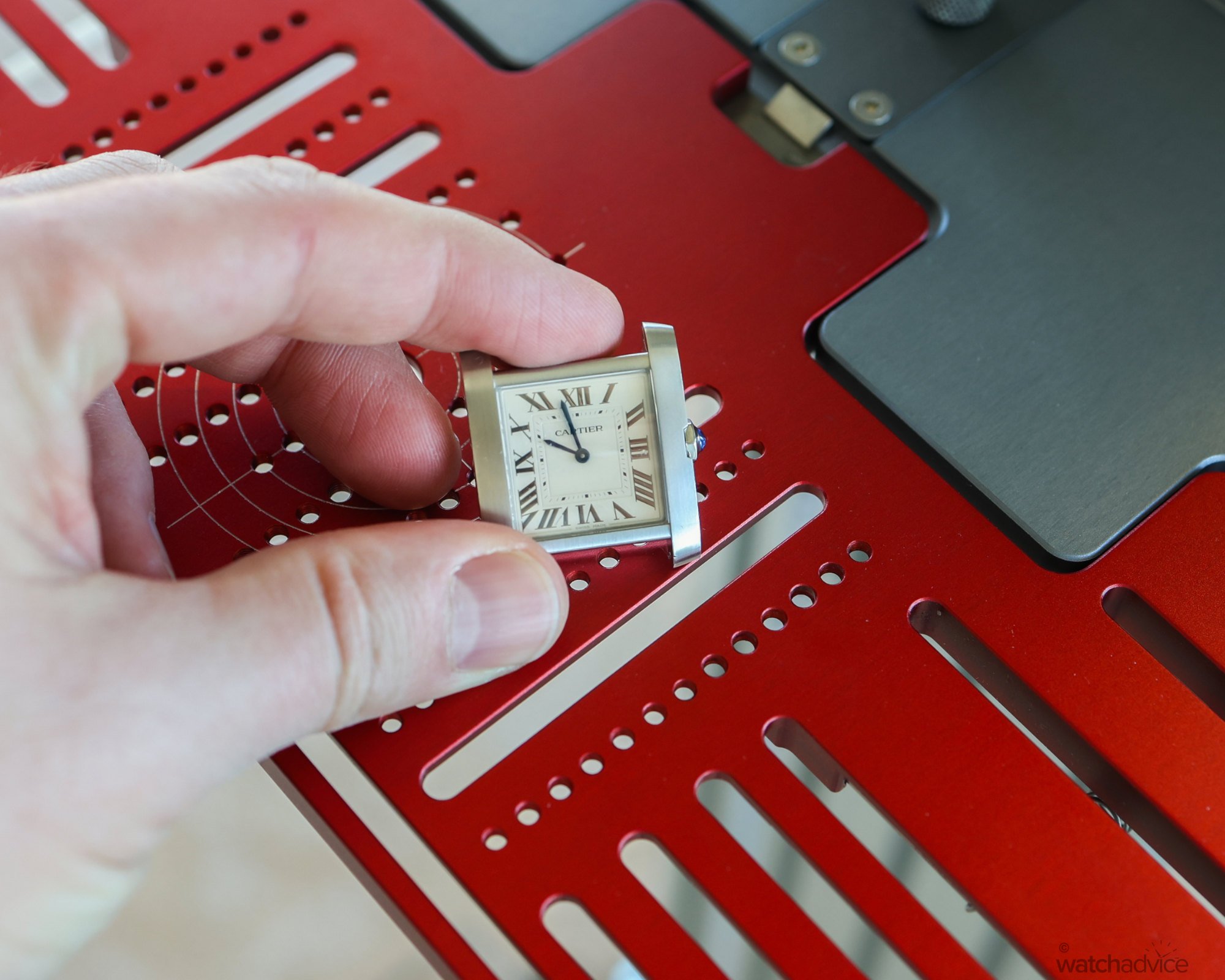

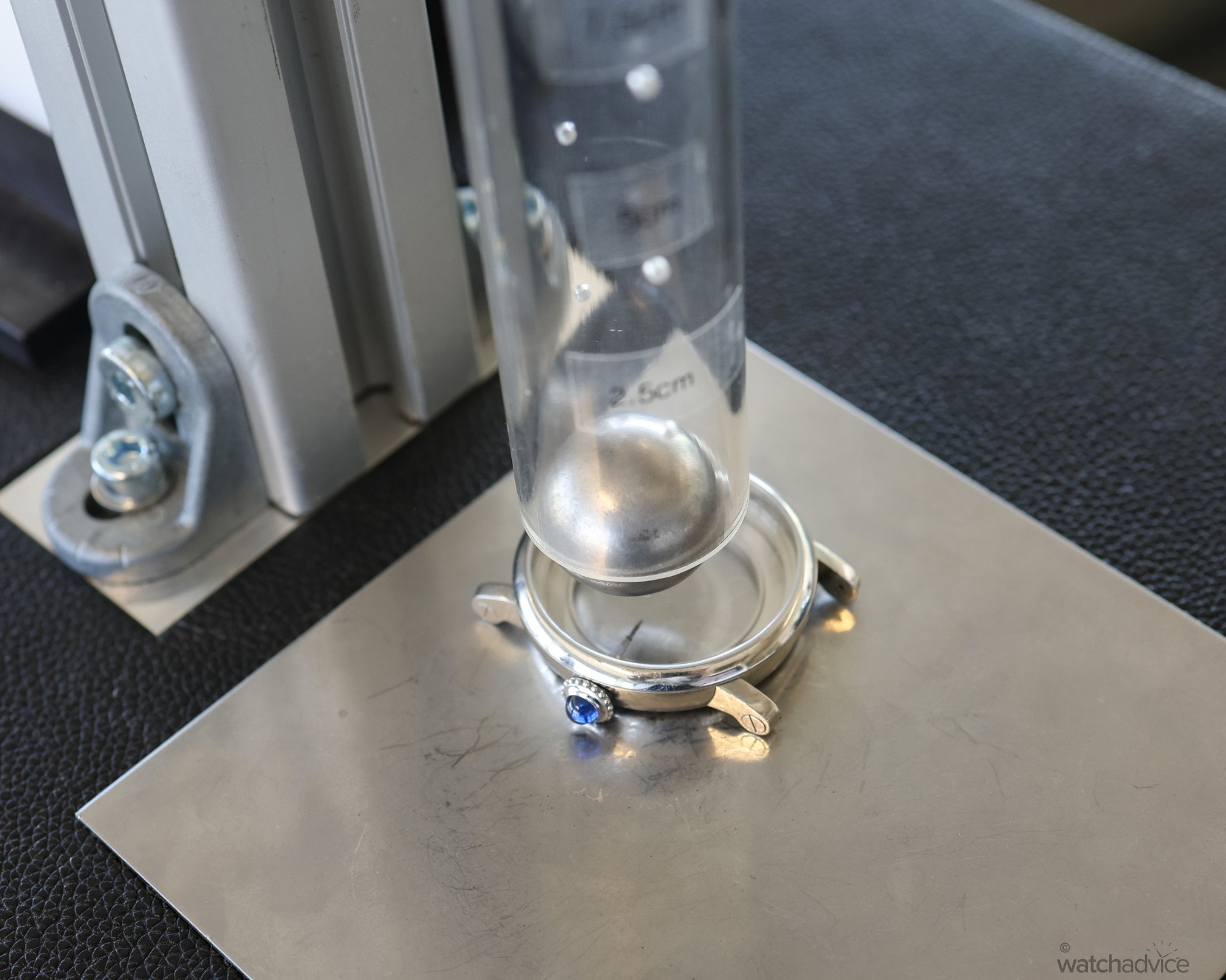

During the development phase, Cartier runs digital simulations of the piece over a 48-hour period to ensure the watch is “theoretically” durable. Once this is done, the team produces a prototype watch, to be put through around 30 tests, simulating approximately 10 years of aging. These tests help Cartier to see what the limit is on their pieces, not to mention their durability. One of these is a shock test done with a steel ball, being dropped onto the watch case from varying heights, emulating how the case, movement, and crystal can take an impact in real life.

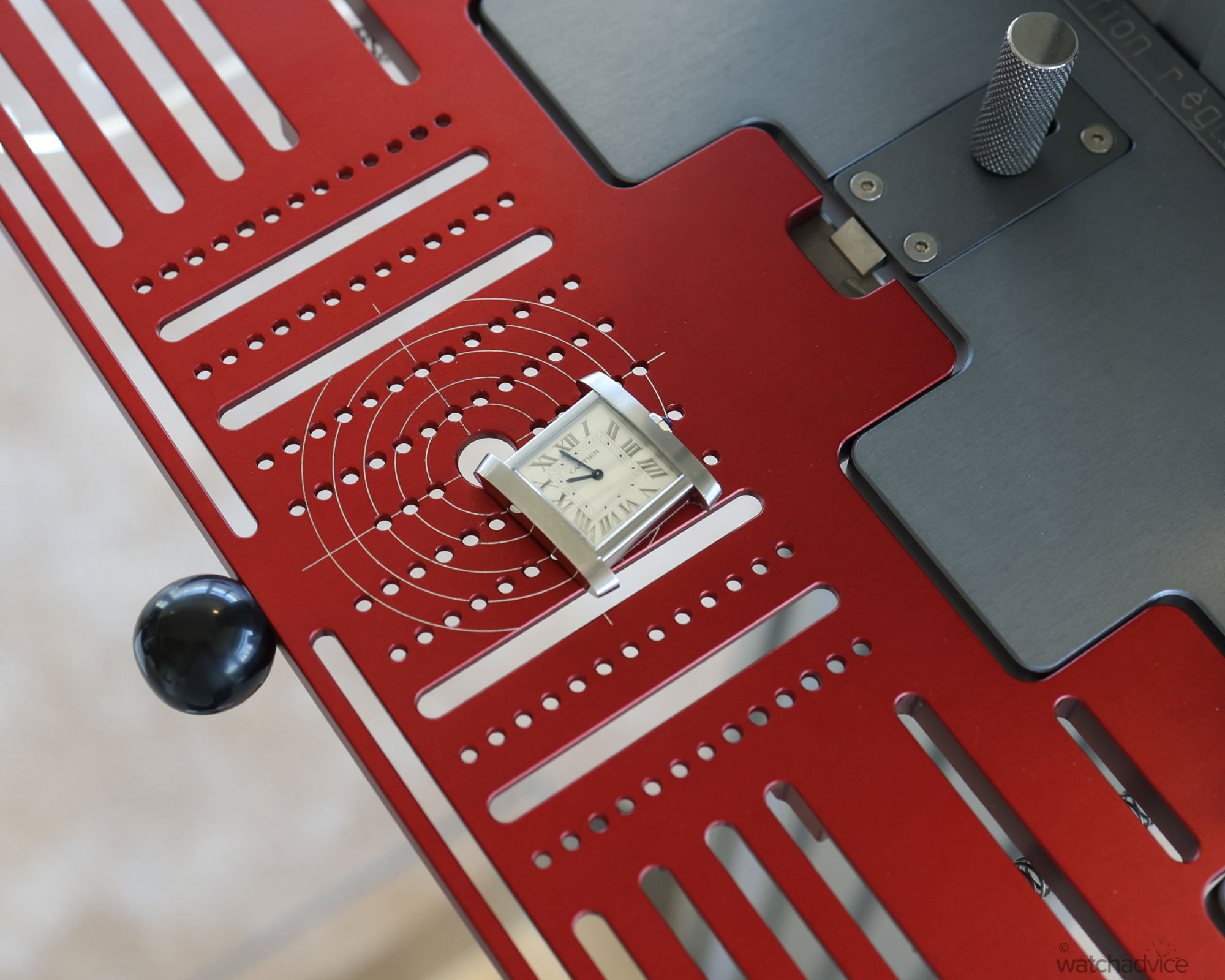

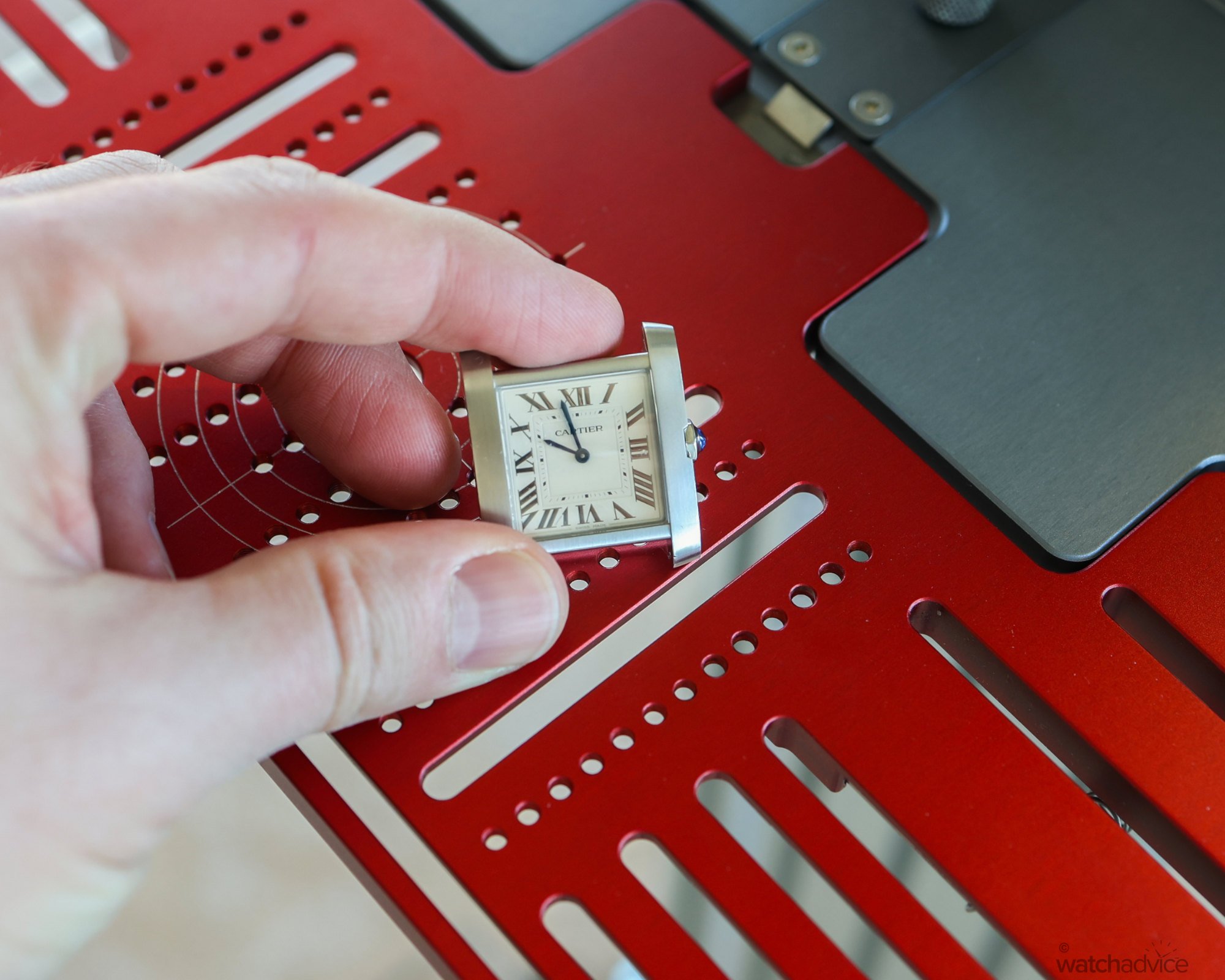

Another of the other tests we had a little fun with was the drop test done on a fully cased watch, in this case, a Tank. Similar to the above, the watch case is placed on a platform from various heights, then the platform is released and the watch drops to the hard floor. This helps Cartier designers and engineers to see how much force the watch can take, and at what point the movement, case, or crystal is damaged as a result of a fall or hard hit.

Preservation & Heritage

We finished the tour of the Manufacture in its repairs and restoration department. Sometimes life does happen and you damage a watch, (as careful as I am, it has happened to me, thankfully only once ever!) or you have a vintage piece that’s been passed down and it requires some TLC to bring it back to its former glory. Whatever that is, Cartier handles all these here in their workshop. We are not able to show these unfortunately due to all the pieces being personal property of individuals however, Cartier does have some very nice historic pieces on display here as part of their effort to showcase their heritage and the preservation of them.

These pieces are a beautiful example of Cartier’s history and the evolution of their pieces. When you look at a watch from 100 years ago, you can still clearly see the design cues that are in today’s modern pieces, which makes you appreciate the brand more. Timelessness, no matter what industry we are talking about, is so hard to perfect in a product. But if you can do this, it will never go out of style and eventually becomes iconic and intertwined with the brand in question. I feel Cartier has been able to do this, and not with just one, but many of their watches. No better examples than perhaps the two below. The first image is of a Santos from 1916, which the current Santos Dumont is modeled on today. The second is a Cartier Tank à Guichets from 1931, with a unique hour and minute disc to tell the time.

As our journey through the Manufacture ends, we walk out of there with a newfound appreciation for Cartier. For me, the main takeaway is that Cartier is a Maison that emphasises craftsmanship. Like all brands these days, machines and mass manufacturing play a part – it has to in order to stay viable as a business. But where Cartier sets themselves apart is the people and their skills that bring these pieces to life. There are very few elements of the watches not touched by a human hand, and in most cases, these skilled watchmakers and artisans craft and refine Cartier watches. From the cases to the movements, the bracelets, and even the crystals. If you have a Santos, or a Tank, or Pasha on your wrist, you have a piece on that has been expertly made and assembled right here in La Chaux-de-Fonds, probably by one of the people pictured here in this article!

This article was written as part of a commercial partnership with Cartier. Watch Advice has commercial partners that work with us, however, we will never alter our editorial opinion on these pieces, a fact that is clearly communicated to the brands when entering into a commercial arrangement.

Image Gallery