The IWC Manufacture is one designed to be visited and seen, and that’s exactly what we did on our recent trip to Switzerland

Written in partnership with IWC

When IWC CEO Chris Grainger-Herr was envisioning the new IWC Manufacture in the brand’s home of Schaffhausen, one of the main goals was to make it so people could enter the world of IWC, get to know both the brand and the watches more intimately, thus allowing people to connect with IWC on a deeper level. What better way to do this than designing a Manufacture that is purpose-built for visitors? This is what we experienced on our recent trip to Schaffhausen, and we saw how the vision has come to life since 2018 when it opened.

Not all watch bands want you to peek into the inner sanctum. After all, it is a highly competitive industry and these days, innovation in movements and cases is what sets one apart from the other. So it is fair enough that they don’t want to open their doors all that often to the general public. Being a watch journalist is different as it helps you understand the brand and you also benefit personally as it’s all part of the education process as well, but with IWC this isn’t an issue. In fact, it’s the opposite as this purpose-built facility on the outskirts of Schaffhausen was designed with the public in mind. To house case and movement making all under one roof while simultaneously being designed so the public, journalists, and watch lovers alike can be guided through the facility and see IWC’s watches being made and assembled.

The Entry

The Manufakturzentrum is a state-of-the-art 14,000 square foot facility, that is both impressive and welcoming at the same time. Having been designed by IWC CEO, Chris Grainger-Herr who is also an architect by trade, is a blend of modernity and tradition with more of a slant towards the modernity aspect. IWC has a long history, dating back to the origins when American watchmaker, Florentine Ariosto Jones left Boston and founded the “International Watch Company” but since then, has gone through a lot of changes over the years from private ownership to now being under the stewardship of Richemont. And today, with Chris Grainger-Herr at the helm, IWC is doing things differently – being less conventional, taking a few more risks, and pushing the boundaries with their performance materials to create watches with more in-house calibers than ever before.

Entering the IWC Manufacture, this is exactly the sense you get. The giant 9-meter-tall lobby done in a mix of glass and wood showcases this, with the CEO’s and founders portraits on one wall, and behind the front desk, a giant Perpetual Calendar movement proudly displayed showcasing IWC’s movement capabilities and love for the perpetual calendar.

Cases and Materials

Moving through the Manufacture, you can see how Chris’s vision has come to life, being set out to facilitate visiting groups to view the manufacturing process from start to finish. Walkways and displays are set up along the tour and designed to educate on all the processes that go into IWC’s cases and movements, not to mention showcasing the raw materials from when they arrive at the facility, such as the bars of different metals used to mill the cases and base movements.

The whole facility is designed to have a flow to it, which in today’s modern watch world is important. Time is money as they say, and the more efficiently you can get parts from one area to the other the more time is saved, the more efficient and cost-effective the manufacturing process is. This means that IWC can spend more time and money on R&D into their movements, like their newly released Portugeiser Eternal Calendar or their case materials, such as Ceratanium.

Good For Another 400 Years

Should you be lucky enough to have a Perpetual Calendar, you will receive an additional year disc which means once the Perpetual calendar has reached the year 2199, you (or your great, great-grandchildren rather) can take the watch back and they’ll insert the new disc, ensuring it will run accurately up to the year 2499.

IWC is known for its performance materials, and we did see some of these being made, however, for privacy and intellectual property reasons, I can’t show you much on this understandably as very few other watch brands are experimenting with metal and ceramic fusions like IWC is. But what I will say is that they are at the cutting edge of this innovation, and when you understand what it takes to develop and put into production at scale these materials, you understand why this is closely guarded.

The Movements

Movement making is always one part of a watch manufacture that fascinates me – and maybe like all good watch lovers, it is one of the reasons we love this industry and hobby. All those little parts moving in sync to tell the time without the need for a battery or any electronics. And for a Perpetual Calendar, not only telling the time, but the day, date, month, year, leap year, moon phase etc all accurate for 100 years, or in IWC’s case now, 400 years and a moon phase accurate to one day in 45 million years when it comes to the Eternal Calendar.

Moving through the movement manufacturing section, it is great to see the transition from the highly technical and accurate machining process, to the pieces being finished and assembled by hand. Again, this whole fusion of modern watchmaking meets traditional. Both science and art come together to make these little machines on our wrists.

Once the movement parts have been machined these are then quality controlled and checked before the movement assembly takes place. This is pretty common practice these days for most luxury watch brands, and where the human eye and hands come into play – along with the expertise of the watchmakers.

At IWC, they have designed the facility to keep the parts moving and people honing their skills on different elements of the movement. This is one great aspect of the modern watch manufacture and ensures that each part and movement is of the highest quality due to the watchmakers being experts in their own right, expertly assembling each movement in the IWC stable.

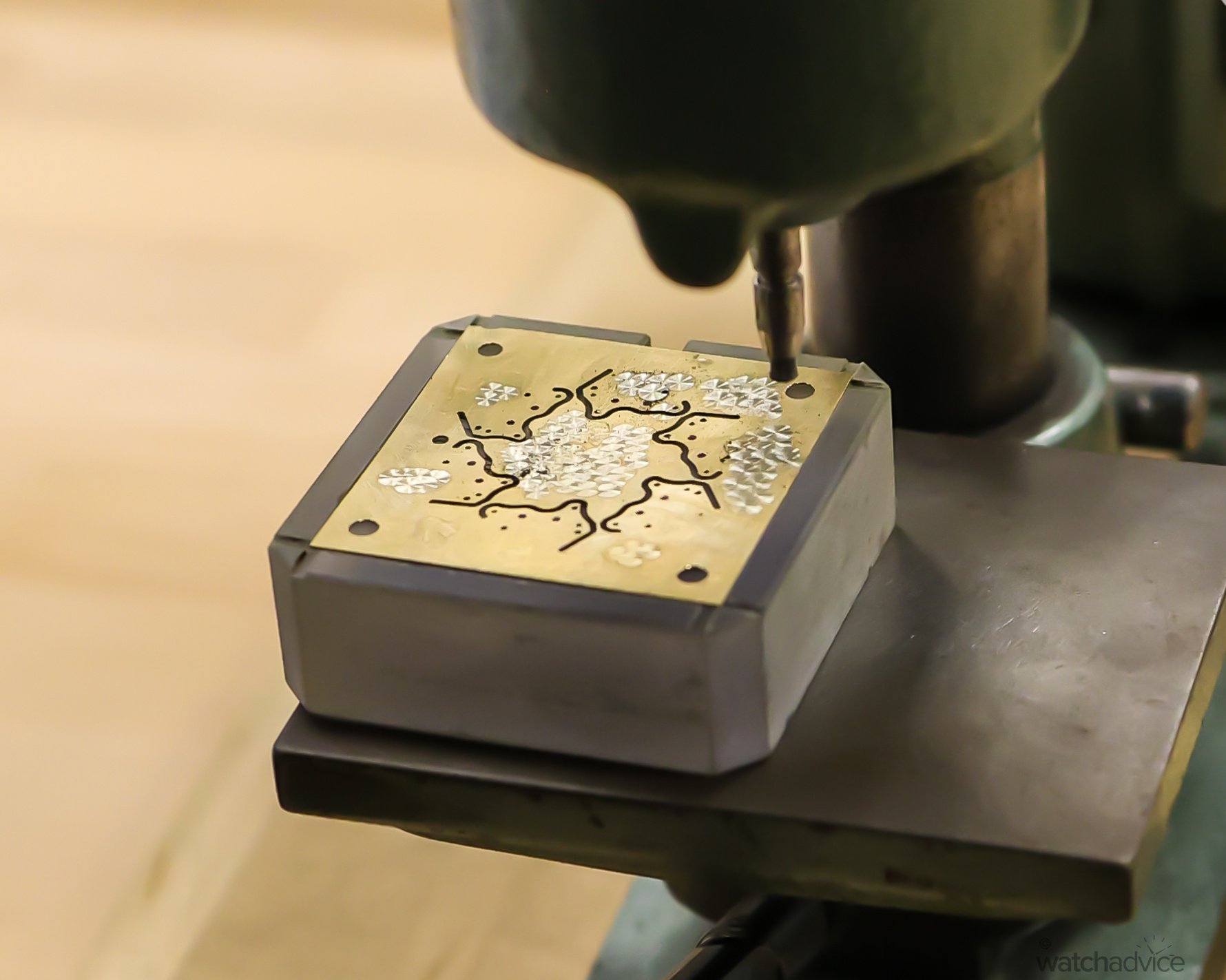

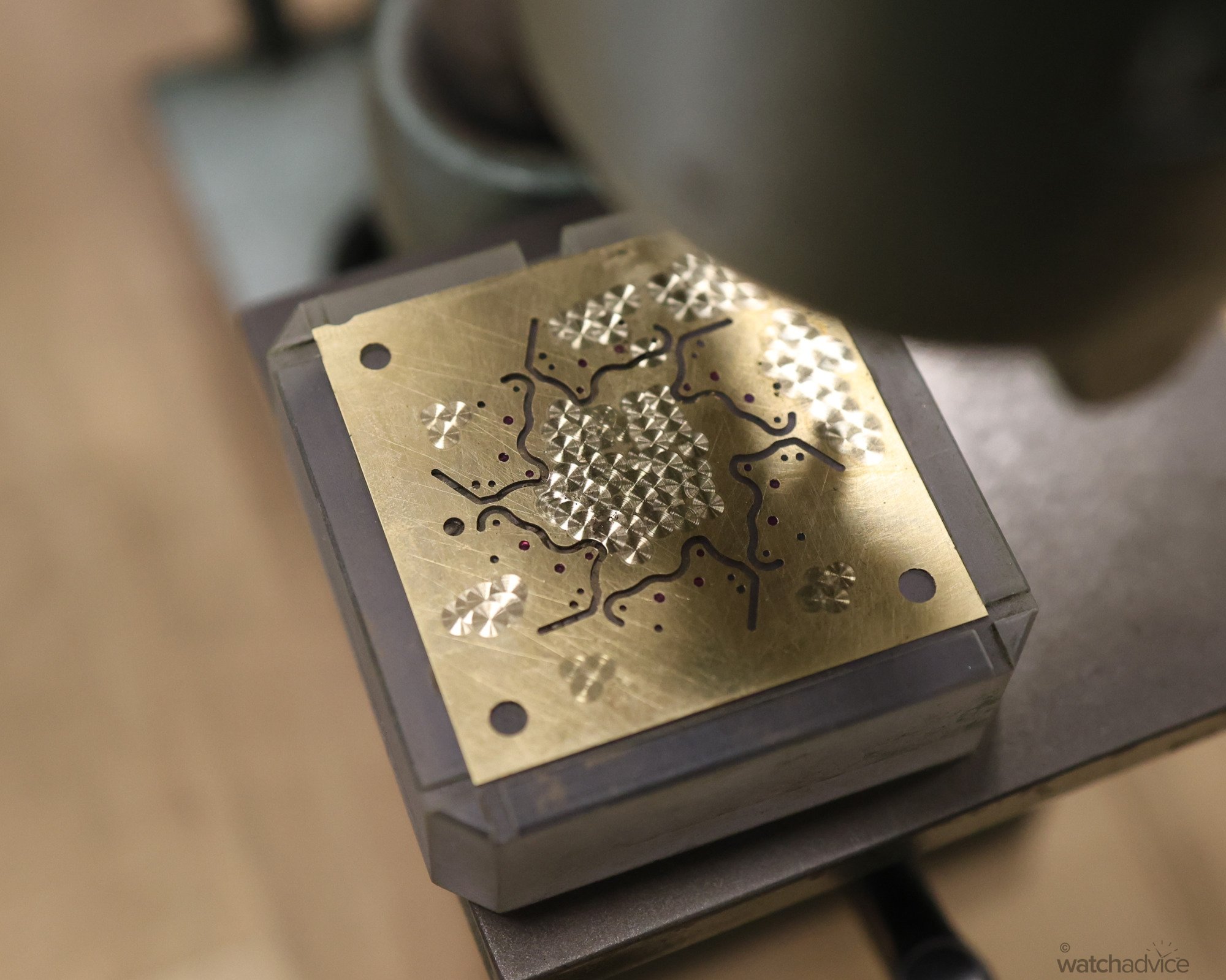

Whilst you can’t get up close and personal with the watchmakers, (understandably for an open to the public facility like this) you can try your hand at a few decorating techniques along the way, such as circular graining, or “Pearlage”

The Art Of Pearlage

This work requires a steady hand to get the pressure and position just right. But when you do, the results are fantastic, and you can see why it’s such a common decorating technique in the industry.

However Pearlage is just one area of finishing and when you look through the caseback of an IWC, you can see all the areas that come into play here to make the movement look the way it does. This is all done via the watchmakers finishing the movements by hand with beautiful results on the bridges and plates – like that below when you compare the un-finished vs finished version.

A Personal Tour

Normally as part of the press, you can get fairly unrestricted access to watch manufacturing facilities and see the inner workings that many won’t ever get to see. What I did love about the IWC manufacture is that it’s open for all to see, and we got to experience this the way any fan of the brand would with our own IWC Ambassador taking us through the Manufakturzentrum who was able to answer all our questions, and we had a lot!

If you happen to be in Switzerland and can make your way to the IWC Manufacture Schaffhausen (about an hour out of Zurich), then I would highly recommend it. The inner watch geek in you will love it, and the countryside around the area is absolutely beautiful – especially around the Rhine and Rhine Falls where you can stop and have lunch and take a few (or many) pictures!

We could have spent a lot longer wandering around the facility and exploring the home of IWC, talking to staff, and digging even deeper into the brand. However, Watches & Wonders was calling, and with the expo starting the next day, we had to say Auf Wiedersehen to IWC, Schaffhausen, the Rhine, and head to Geneva.

If you are interested in understanding more about how watches are made, or want to get under the hood of what makes an IWC tick (yes pun intended here!), then we would recommend taking the tour. Even if you’re not going to be in Switzerland why not plan this and make a holiday out of it?! You can register via their website here.

This article was written as part of a commercial partnership with IWC. Watch Advice has commercial partners that work with us, however, we will never alter our editorial opinion on these pieces, a fact that is clearly communicated to the brands when entering into a commercial arrangement.