The third part of our Watch Escapement series highlight’s Girard-Perregaux involvement in revolutionising the modern watch escapement. WatchAdvice’s watch escapement segment so far has highlighted the history of the escapement and what led to the modern escapement being formed (which you can read here), along with Rolex’s modern adaptation with the Chronergy Escapement (read here) and Ulysse Nardin’s innovative Anchor Escapement (read here).

The third part of this series looks at one of the rarest watchmaking escapements with Girard-Perregaux’s design and how they came up with a revolutionary way to improve the modern escapement design. Much like Ulysse Nardin’s design for their Anchor Escapement, Girard-Perregaux also employs blades that buckle to release tension. Girard-Perregaux’s constant force escapement design has been around for almost a decade, but that doesn’t make it any less important in the modern world of horology.

To first create the constant escapement, Girard-Perregaux looked at the shortcomings of the modern lever escapement. The first is the chronometric rate drop due to the watch being adjusted and having the mainspring unwind again, which leads to a loss in precision due to amplitude changes. The second problem is the amount of friction. With the standard lever escapement design, the lever touches the escape wheel, with the pallets then locking and unlocking against the escape wheel’s teeth. Friction also exists when the lever touches the balance wheel. Not only does more friction means less accuracy in the long run, but the more parts there are that cause friction the more oil and regular maintenance required.

Girard-Perregaux’s ingenious solution to these problems is presented with their Constant Escapement. The problem of precision is mitigated thanks to the Constant Escapement’s consistent power output, and with a consistent amplitude, a constant force is given. Like Ulysse Nardin’s Anchor Escapement (see below), the Constant Escapement is able to almost minimise friction to zero. The key feature that helps this occur is the buckle blade made from silicon.

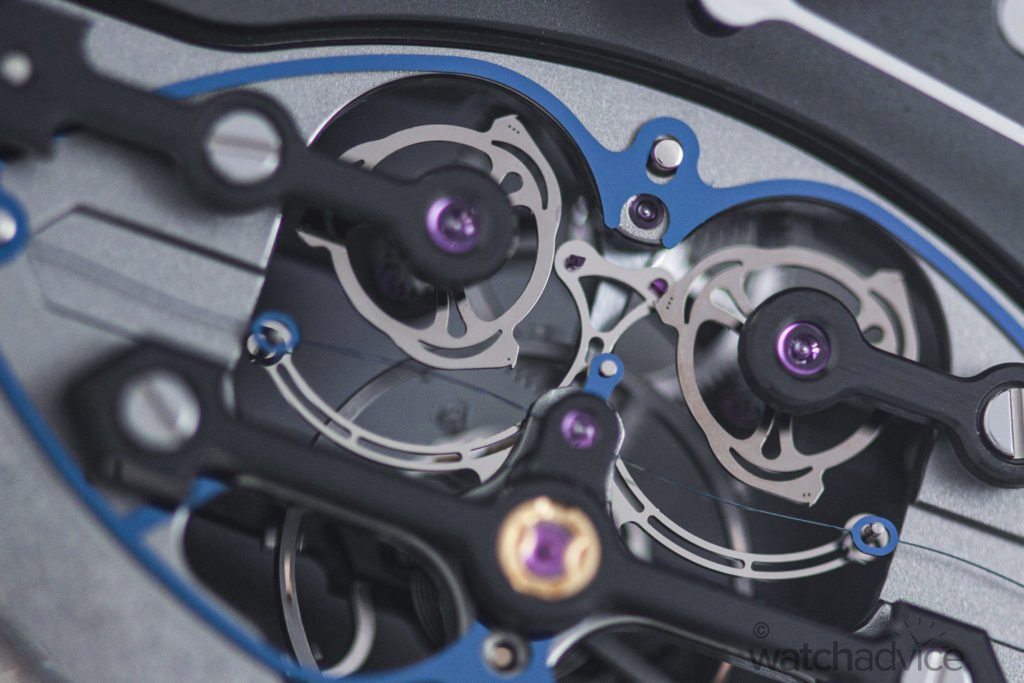

Girard-Perregaux’s Constant Escapement also uses two escape wheels, a feature not seen in too many movements. An ultra-precise lever is used as the “locking and unlocking” on the teeth of the escape wheels, with this increased precision then further reducing the amount of friction involved.

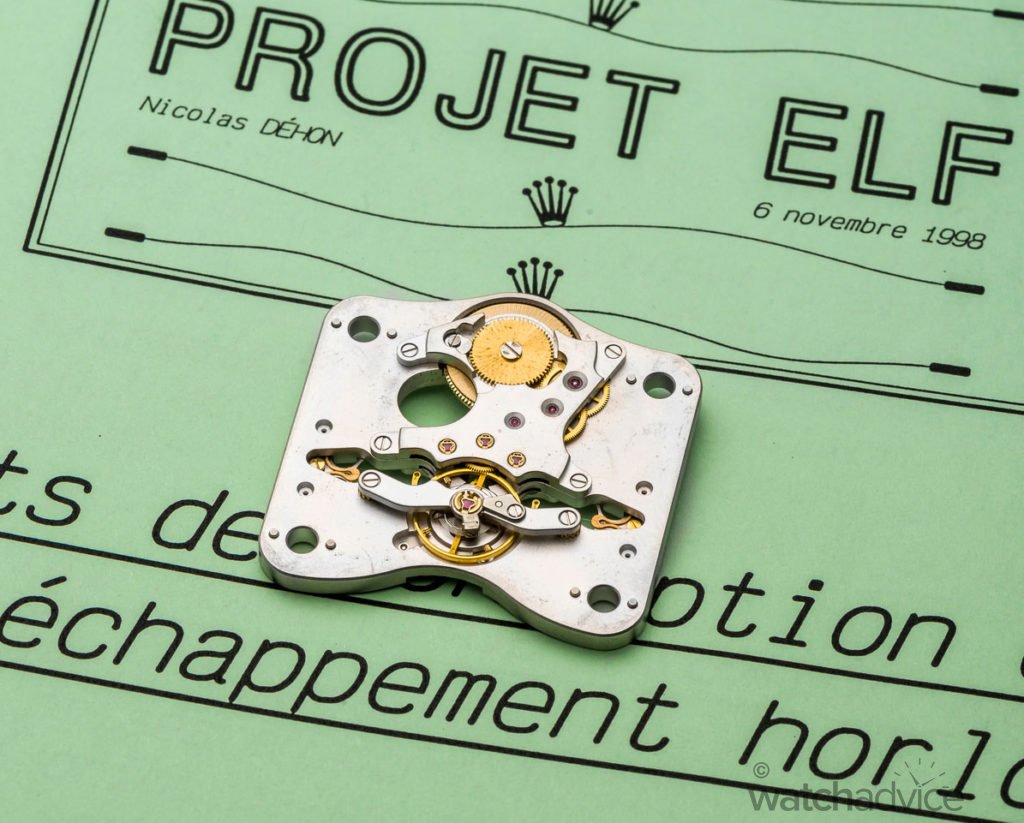

So how did the idea of the Constant Escapement first come to fruition? Funnily enough, the story of the constant escapement starts with Rolex and a research and development engineer, Nicolas Déhon, that dedicated almost 10 years of his life to this design. TheWatchBox did an interview with Nicolas Déhon, in which he states how the idea for a new escapement design came to him.

“Dehon was commuting by train when he had an epiphany while absentmindedly flicking his ticket between his fingers. A blade spring, kept slightly flexed between two fixed points, could like his train ticket be made to snap back and forth, delivering a predictable pulse of energy each time. If the bit of cardboard between his fingers could be transformed into a source of energy for balance, it might be the answer to the constant force riddle.

The process of development began, and though Dehon and Rolex were able to cobble together a prototype, and even took out a patent for this constant force escapement (granted in 1999) its design was still slightly ahead of its time. The materials needed to build a reliable and effective version were not available.”

This unfortunately was one of the reasons why Rolex didn’t put the escapement into production. The brand is all about reliability, and with the material knowledge available at the time of development, Rolex wasn’t able to produce a reliable enough escapement. The Constant Escapement, however, once it’s set up properly with the right materials, is one of the most reliable and precise escapements available.

The year 2008 is when silicon made its way into the watchmaking world, with research into using silicon in escapements taking place at the Swiss CSEM (Centre Suisse d’Electronique et Microtechnique). This lab was essentially funded by Rolex, Patek, and Swatch Group. Ulysse Nardin had their own work carried out on the use of silicon which they were able to utilise in their Anchor Escapement and their very first Freak timepiece. It wasn’t until Girard-Perregaux came along that Silicon would be considered the ideal material to revive the Constant Escapement. After several years of research and development, Girard-Perregaux was able to create a working prototype of the Constant Escapement and fit it into a working timepiece.

How Does Girard-Perregaux’s Constant Escapement Work?

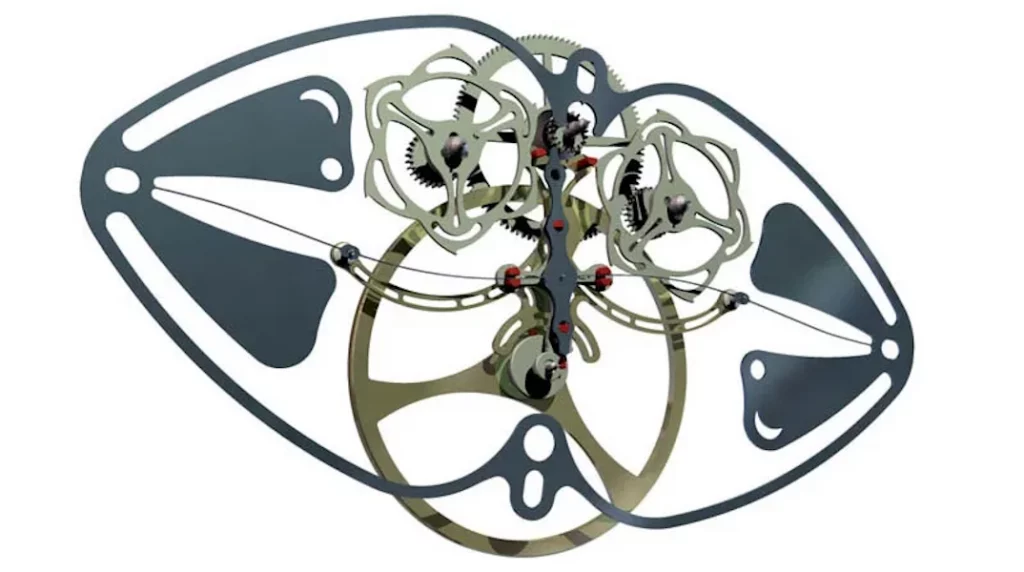

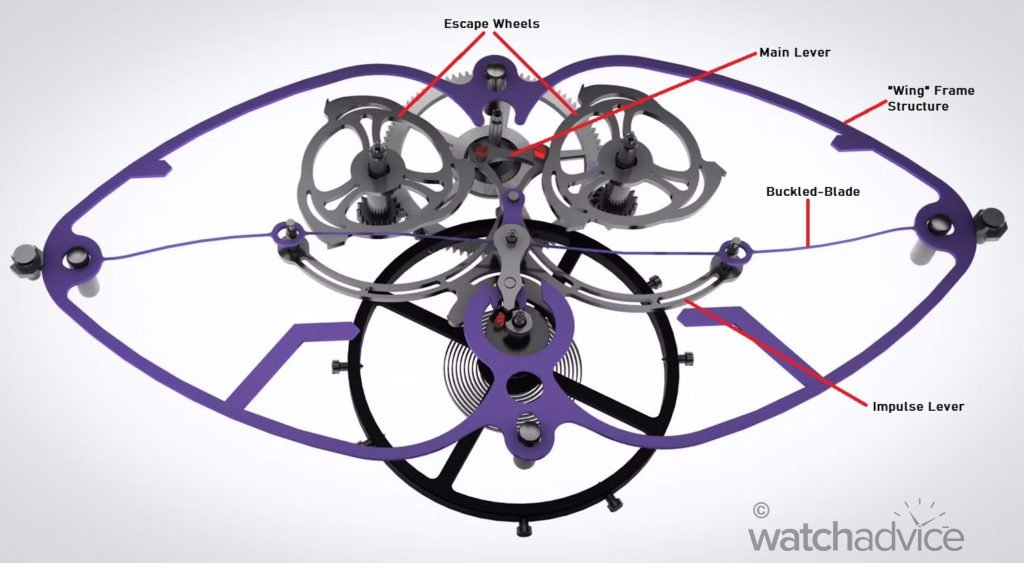

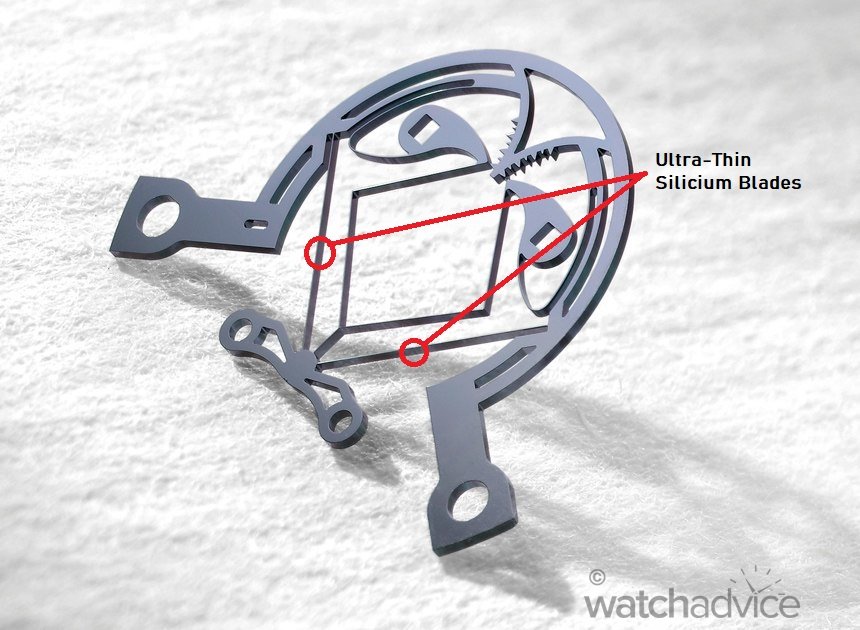

The unique design of the Constant Escapement is certainly intriguing, especially the wing-like spring frame. There is a purpose to all the design elements, however. On either side of the wing-shaped structure is a connection of a thinner-than-human hair (6 times thinner!) buckled blade. It runs along the horizontal span of the “wings”. This ultra-thin buckled blade is how Girard-Perregaux was able to make the Constant Escapement work.

At either point of the spring frame, the buckle blade will sit straight when at rest. There are two “impulse levers” which are connected to the buckle blade on either side of the “wings”. When these impulse levers move up and down, they release a micro millijoule. Even with such a tiny release of force, it’s able to increase the power reserve drastically.

The impulse levers move as the escape wheels turn. The lever and impulse levers are all made of one part, which means they all act in unison. When the lever moves, the impulse levers will move up or down on either side. Putting this into practical use, the escape wheels and lever act in the traditional sense of Lever Escapement (which you can read here). When the right escape wheel turns, the lever will lock into the teeth of the wheels. As the right escape wheel moves again, it will unlock and release, which then swings the lever onto the left escape wheel, and then locks onto that wheel’s teeth. This process is then repeated back and forth like the lever escapement design.

As the lever and two impulse levers are all made of a single part and connected together, as the lever swings back and forth from the two escape wheels, each of the impulse wheels will move up and down (as left goes up right goes down etc). This then proves a minuscule in movement to the ultra-thin silicone buckle blade which is what ultimately gives the watch the power.

Girard-Perregaux designed quite a few watches with their Constant Escapement mechanism, with the most notable timepiece being the Constant Escapement LM. Design to showcase fully the Constant Escapement mechanism, this timepiece was stunning work of art. The Initial L.M stood for Luigi Macaluso (1948 – 2010) who acted as president for the Sowing Group which owned Girard-Perregaux. He was also the that pushed for this movement to be made.

This particular timepiece featured more than just the impressive Constant Escapement. The GP09100 movement in which the Constant Escapement sits featured two double barrels, which had springs that measured a total length of 3 meters when unraveled. This equated to a total of 7 days of power reserve! Combined with the ultra-precision of Girard-Perregaux’s Constant Escapement, saying that this movement is impressive is an understatement.

Girard-Perregaux’s Constant Escapement changed the way escapement design is viewed for high-end luxury timepieces. The escapement was made possible thanks to the early work of Nicolas Déhon, and if silicon material knowledge had been around at the time of his research and development into the escapement, Rolex will have been the first to create a reliable Constant Escapement. It was, however, Girard-Perregaux that took the onus and finished the task but used their own unique design and knowledge of silicon to create the buckle blade.

Keep an eye out for our next article in this escapement series, where we will look at the design of Charles Frodsham Double Escapement.