Earlier this month, we looked into Rolex’s Chronergy Escapement as part of our Modern Watch Escapement Series, which you can find here. This was a continuation of our introduction to one of the most vital components in mechanical watchmaking, The Watch Escapement.

In today’s Watch Education article, we look into a different escapement system that’s not the standard lever escapement used throughout the watch manufacturing industry. While Rolex took the trusted lever escapement design and added their own modifications to make the escapement more efficient, Ulysse Nardin has taken a different approach with their anchor escapement design.

Ulysse Nardin’s Anchor Escapement system was first unveiled during Baselworld 2014, which was probably the first time a watch company has unveiled just an escapement design during Baselworld. Ulysse Nardin has contributed so much to the advancement of mechanical watchmaking that it shouldn’t really have been a surprise when the brand unveiled a revolutionary escapement design.

To give a quick background on what an anchor escapement is, it was invented to improve isochronism and has mainly been used on pendulum clocks. Shaped like a ship’s anchor, the anchor escapement design is to contain mainly two parts, the escape wheel (wheel with teeth), and the anchor, which swings back and forth on a pivot against the rotational movement of the escape wheel. Have a look at our introduction to watch escapements if you want to learn more about the components that make up an escapement mechanism (click here). Now, while a standard anchor escapement design uses a pivot point much like a lever escapement to swing back and forth from, Ulysse Nardin’s design completely negates this.

One of the reasons why an anchor escapement design hasn’t been considered for wide commercial use before was due to its practical use in timepieces. The main disadvantage of using an anchor system was the recoil and friction. Ulysse Nardin was able to mitigate this thanks to their extensive research and development into Silicium technology. Ulysse Nardin states that “Silicium is a metalloid, a type of chemical element that resembles metal without possessing all of its properties, in particular its hardness. Its usage has been generally applied in the sector that mainly manufactures semi-conductors, transistors, and microprocessors, which use the material as a base for etching micro and integrated circuits. It presents a series of properties that make it perfectly suitable for use in micromechanical precision, a field that includes watchmaking.” Thanks to the elastic properties of Silicium, its flexibility allowed Ulysse Nardin to negate any recoil problems.

The late Rolf W. Schnyder, who was the owner of Ulysse Nardin, set up another company called Sigatec. First founded in 2006, Sigatec is a company specializing in the manufacture of micromechanical components in Silicium. This allowed Ulysse Nardin to get first-hand knowledge and experience working with Silicium . Knowledge, experience, and developments that led to the creation of Ulysse Nardin’s Anchor Escapement, after seven years of hard work.

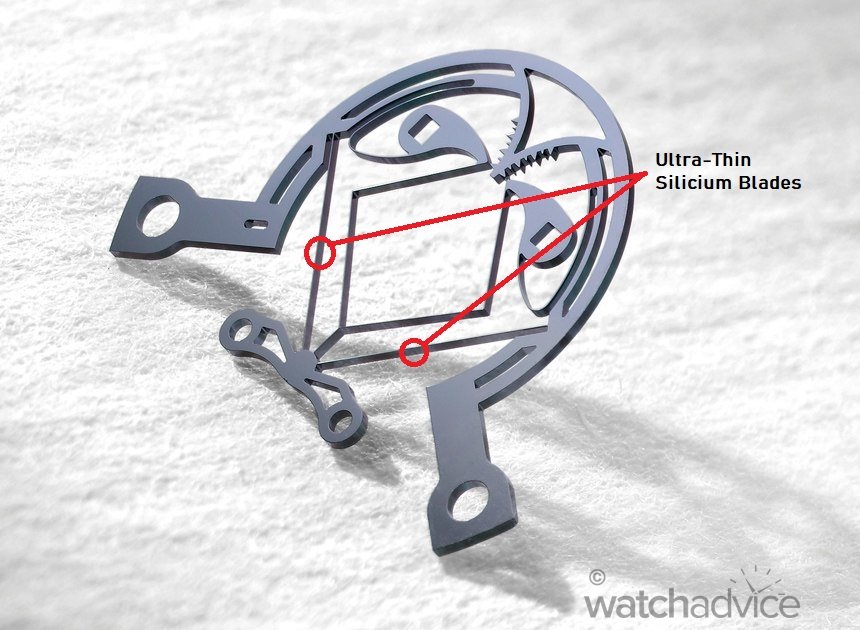

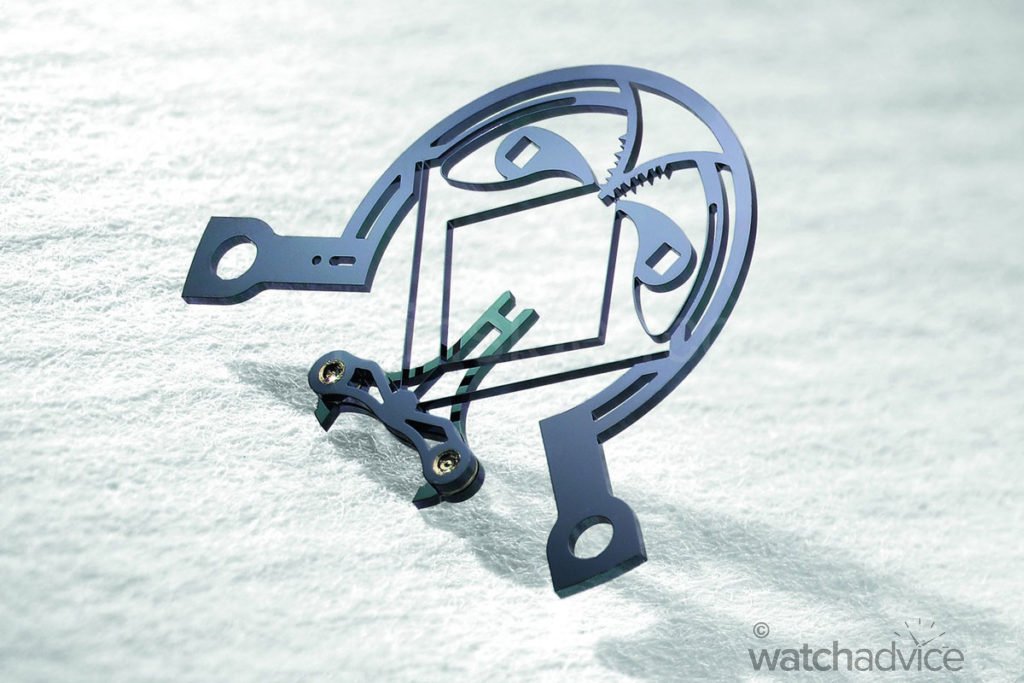

At first glance, Ulysse Nardin’s Anchor Escapement has a very unique design. The circular Silicium frame was designed in a way to negate the use of a pivot, with the pallet arms now being suspended by ultra-thin Silicium blades. The blades have a thickness of 15 micrometers and are approximately 4mm long.

So how does this all work? Firstly, it’s all thanks to the properties and strength of Silicium material. As the escape wheel turns, the pallet does the normal job of locking and unlocking onto the escape wheel (see our education article on Rolex Chronergy for a detailed explanation of this process here), however, the pallet needs to be able to pivot back and forth to transfer the energy across, which it isn’t able to in this case without the pivot. This is where the ultra-thin silicon blades from Ulysse Nardin’s escapement design come in.

As the escape wheel rotates and the pallet “locks and unlocks”, this motion would get transferred back to these Silicium blades which will then “curve under tension” and buckle one side to another, being perpendicular to another. As the pallet “locks” onto the escape wheel, one of the silicon blades would bend, while the other remains perfectly rigid. Then as that pallet “unlocks” and the other pallet locks, the blades would switch, with the previously bent one now becoming rigid and the previously rigid one now bending to accommodate for the pallet fork pivoting.

You would think that this would put quite a bit of wear-and-tear on these ultra-thin Silicium blades. When you think about it, a frequency of 21,600 (Vph) would mean that that’s how many times an hour the pallets “lock and unlock” on the escape wheel, which is also how many times the thin blades would undergo bending. The reason that Silicium is able to withstand this is due to the material’s yield strength. Provided that the stresses applied on the material are far less than its yield, it can, in this case, keep “rocking back and forth”. Impressive would be an understatement to say the least in regards to Ulysse Nardin’s extensive developments to achieve this final anchor escapement design.

By removing the pivot of the lever escapement design, and having this new anchor escapement, Ulysse Nardin is able to pivot side to side without any friction at all (no pivot remember), and when it returns back to the starting position, it is able to give back stored energy without any loss of energy as well. The overall escapement design is slimmer too, as there is no bridge for the pallet lever. And finally, another benefit is the lack of lubrication involved. As there is no friction of materials, no lubrication is required.

With Silicium, Ulysse Nardin was able to revolutionise the lever escapement design and improve the efficiencies, durability and also the size of their movements. The anchor escapement design is one of the few escapement designs that Ulysse Nardin utilises. With that being said, however, the anchor escapement can easily be spotted in movements of most modern Ulysse Nardin timepieces, showing just how good the design is since its release almost a decade ago!

Keep an eye out for Watchadvice’s next education article on the Modern Escapement Series, where we have a look at a similar design to this Ulysse Nardin one; The Girard-Perregaux Constant (Force) Escapement.